Hi All,

I’m looking to dip my toe into framebuilding, but am not quite sure where to start as far as making something that fits what I’m interested in, but also is rideable.

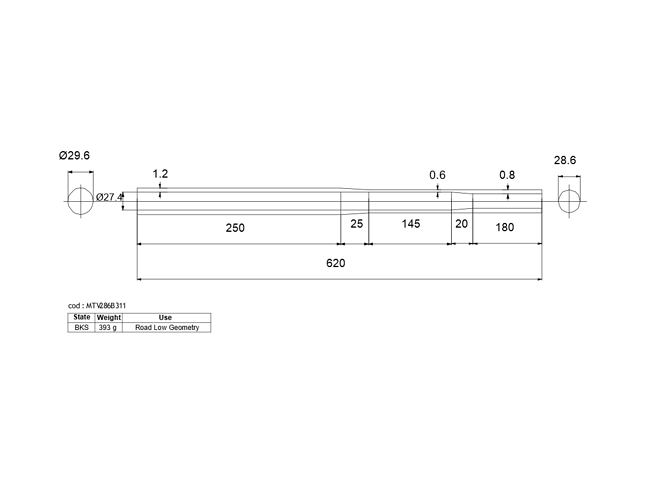

I’ve taken a lot of inspiration from the very talented Colin Woof, as well as Arian Bronner’s Apriko fork, and while I’m not worried about the fabrication details, I have no idea how to determine if I’m setting myself up for something terrible to ride.

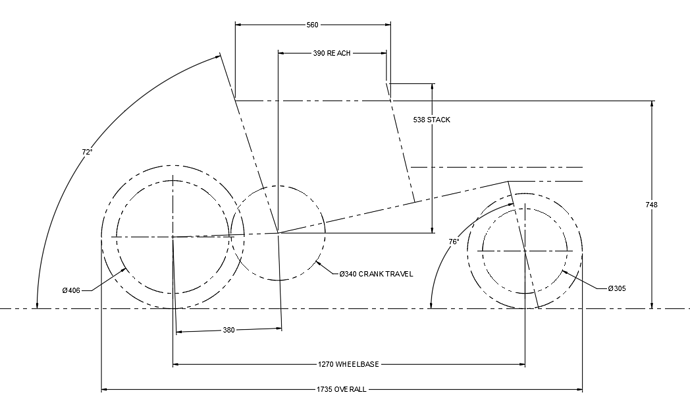

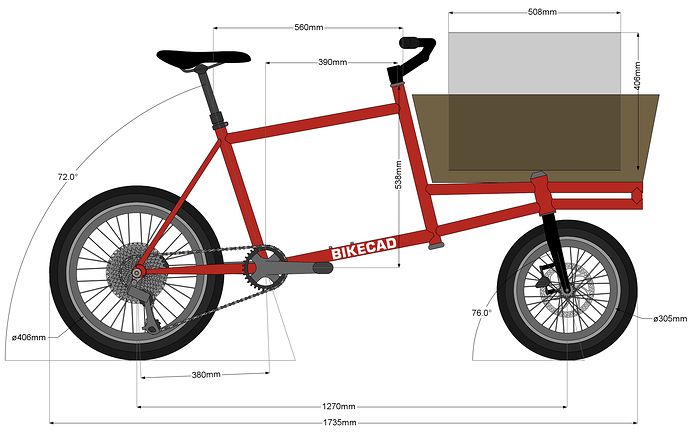

What I’ve drawn out below is a hodgepodge of dims from my current commuter bike, which is the only bike I’m really familiar with, as well as some input based on the Velo Orange Neutrino (simply because it’s a minivelo with pretty well documented geometry) and from the Omnium Mini.

The goal is a mini cargo bike that doesn’t take up much space and can haul a window air conditioner unit (20L x 16H x 14W ~45lbs). If it can fit that, it will happily fit all sorts of other things I’d want to haul around.

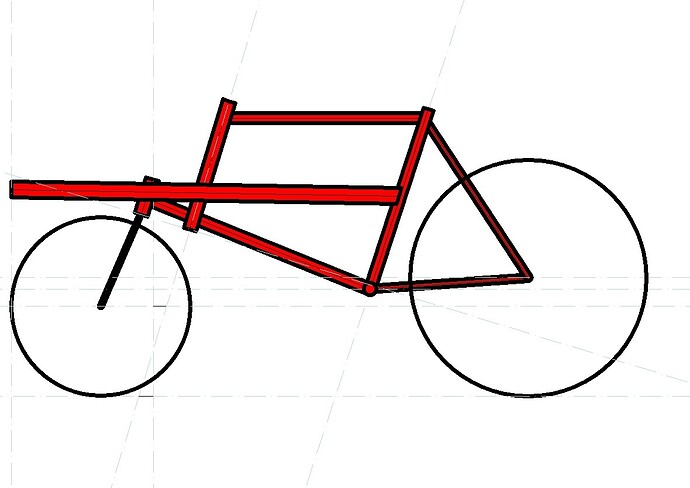

The lines here approximate the center lines of the tubing. The plan is to braze or tig this up from straight gauge 4130 steel, something a little heavy just so it’s easier to work (.049in wall). I might need to buy a seat tube, doesn’t seem like any stock tubes work nicely with common seat post diameters. Probably a simple segmented or biplane fork at the front, trying to avoid any bending for now.

Aside from input on the geometry, I’m also wondering about whether it would make more sense to have the bend in the bottom tube before the steering/head tube (a la the Omnium Mini), and whether I’m setting myself up for clearance issues with my heels and the short chain stays.