I have really loved Hayes Dominion brakes. They aren’t quite as on/off as shimano but I find they have more power than SRAM Codes. They might not have the shortest pull, but it can be set close to the bar reliably and they have the smoothest, lightest lever action I’ve ever felt.

imo Hope Tech4/E4 brakes are the best you can get! I could never abide by SRAM mtb brakes.

I’ve had very good experience with Hayes dominion and TRP dhr evos. Great performance and easy to work on. I’ve had magura MT7s and they are fantastic…until they need maintenance. Then they’re comparatively a big headache to the other 2.

Chain clearance

Pedal clearance

Tire clearance

Left dropout welding was a nightmare. No room, can’t see, scratch tig etc. I butchered it. Maybe I will reinforce it somehow.

Just some pictures

That looks absolutely miserable to weld!! I’d personally brass braze that joint.

I have had a few days of much needed rest. This is how far I’m.

So far quite happy. I did blow 2 holes. One because I had a little gap and forgot about it. Then I did not make a breathing hole, even though I wrote on the tube so I do not forget about it. And one dropout was a nightmare, but I managed to close it after manymanymany… heat cycles. But they look awesome.

When the brakes arrive, I’ll start figuring out the brake location and then weld it all together with 2 tubes in the front.

Great work. I want to build an FS after this. Wish my CAD skills were better

You want Curtis style rear with straight tubes? I’m asking because only hard part is to get the chain/tire/pedal clearance right. Otherwise it is not harder than the hardtail you built.

Yes I do. I like the style of the Curtis style rear end.

I did not know how to use fusion when I started building mine. Watch a few youtube videos and have a go, and we have a fusion thread somewhere in here.

You can find the chainring dimensions and location, Tire width and height, pedal dimensions. Make the dropouts off-center so the axle is lower - this way you get a little bit more chain clearance, best would be to bend the chainstay a little, like Curtis has done. But what do I know, I have not built a bike, no idea if this thing actually is rideable ![]() . But it clears everything.

. But it clears everything.

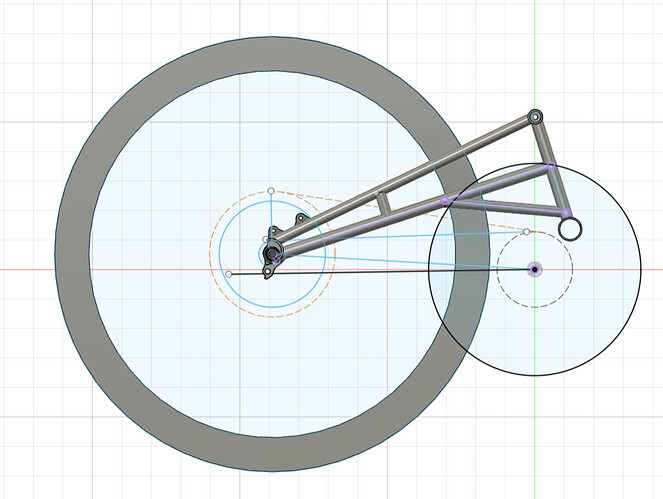

This is what my model looks like. Front has chainring and crank diameters. Rear has 11t and 51t ring and brake disc. All are positioned where they should be. It is a messy image and I’m the only one who understands it, but turning the image I can see it clears everything. Figure out what exactly you need help with and you shall receive, but start sketching.

Been welding and bending. Lots of work.

When I welded the rear together, everything needed aligning again. Got the main pivot and shock mount location fixed, but the wheel is still crooked. Tried to bend it, but nothing seems to help, I probably need some vertical aligning, but I couldnt figure out how. One chainstay is definately higher and probably shorter ![]() . Need to make fixture or maybe I can use my jig somehow. Might not feel it when riding, but it just looks off and bothers me.

. Need to make fixture or maybe I can use my jig somehow. Might not feel it when riding, but it just looks off and bothers me.

IF nothing else, I can modify my left dropout and make it off-center.

Managed to sqeeze a little bit more out of this year.

I rushed it so not very happy. Made it from 4mm s355. Dont like that it is welded to the side of a tube, not sure if it is going to hold up.

Magura calipers look cool

It’s quite amazing this is your first build. Good inspiration.

To do list is getting short. Adjustable font shock mount next.

I need a 170 fork. Can’t decide if I’m going to try my luck with Formula Selva S or go with simple Yari and upgrade cartridge.

Pics

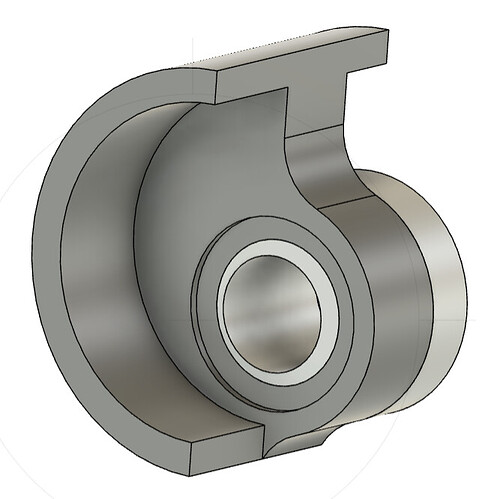

A little overkill?

Cable/housing guides next. I have been thinking of tin soldering, if my soldering iron gets hot enough. Why is tin soldering considered bad? All I have read is that it is not strong enought - not sure I agree. Any problem with painting?

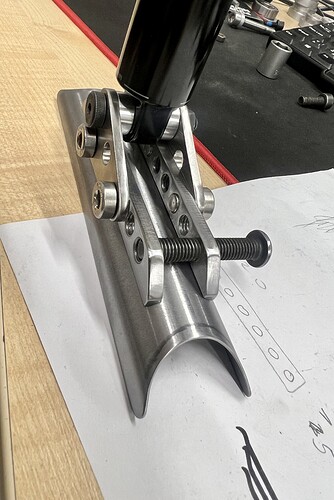

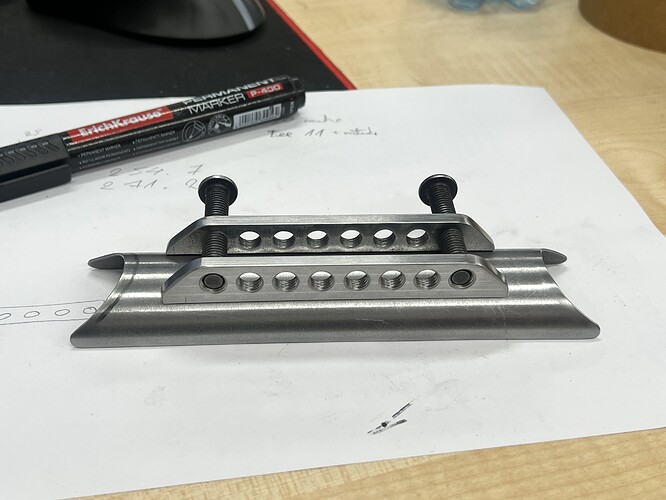

Weeks progress - Front shock mount designed to acommodate 210 - 250 mm length shocks, just by moving the side plates ( geometry is going to stay the same). Why? I can make a trail bike with 210x50 (127 mm travel) shock if I want to, or test different shocks etc.

Welded parts are 5 mm mild steel. Side plates 4 mm 316L. Bolts m8x10 A4.

I made the side plates as low as possible atm. If I want to mount my shock the usual way, I have to make taller plates. Holes and threads I made with CNC mill, rest is angle grinder and elbow grease. Tire to seatpost clearance 13 mm, seatpost to rear shock eye clearance 4 mm.

So basically it should be a functioning bicycle if I assemble it.

Looking great, I like the adjustable shock mount. Tin solder may possibly be strong enough but I don’t think I would want to risk it myself if you are going to do a nice paint job. Would be a real pain to have to repair/redo you paint job because a cable guide popped off.

You could get some silicon bronze and tig braze the cable guides on, I did that on my first two frames and they are still holding on strong. Just make sure you get the silicon bronze that is for tig, apparently its a little bit different to silicon bronze for torch brazing

I could get 1.6mm silicone bronze rods. Too big? How many Amps it needs?

I got lift TIG so it is quite difficult not to melt it with base metal.

I think 1.6mm would be fine. Low amps, and push the filler in pretty quickly to prevent the base from melting. Just need a little blob in each corner to hold it on.

If you have some offcuts maybe just have a practice to try put a little blob on the surface of the tube without melting the base, I cant remember how many amps when I did those but I didn’t have a pedal at the time.

A little something different from frame building .Turns out that swapping non-boost hub to boost is not just a simple hub swap. Since my plan is ruined, I’m thinking of building new wheels myself.

I have watched a few youtube videos and used 3 different spoke length calculators and got 3 different results. So I’m quite confused. Maybe someone can help me out?

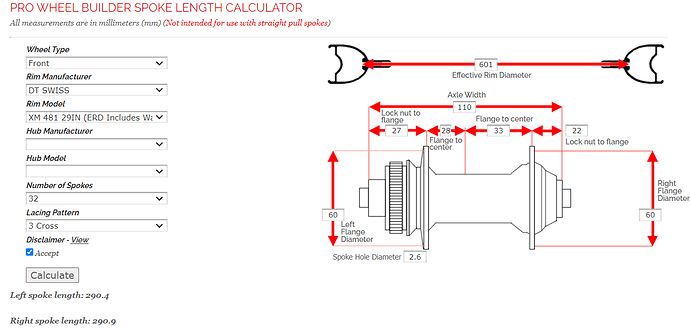

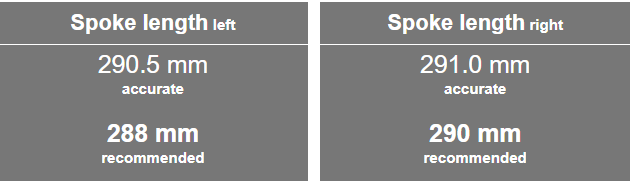

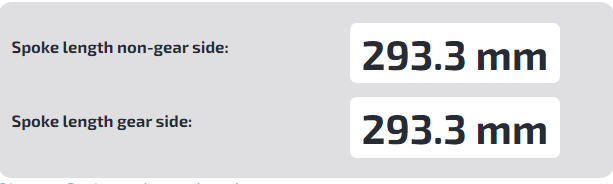

Front hub example:

Wheel DT SWISS xm 481 29 32 spokes - XM481

Hub Superstar V6 - specs are wrong on the website.

Dt swiss calc

Sapim

prowheelbuilder

So what is the correct length?

Without seeing all the input data it’s hard to say but seems like the DT Calculator and the Prowheelbuilder one are giving you the same result, 290.5 left, 291 right.

If you’re stuck using spokes in 2mm increments then I would use 290 left and 292 on the right. I try to avoid rounding down more than 0.5mm. If you can find 291’s then I’d use them on both sides. I know they’re availiable on Bike24 which is where I usually buy spokes from.

Could not resist and screwed some parts on. It has half a degree steeper head angle, but otherwise looking like a bike.

Cleaned some welds and made the dropouts and shock mount a little more aerodynamic ![]() . And ofc Those are non boost wheels. Magura I spec ev adapter are not properly fitting. So still lots to do.

. And ofc Those are non boost wheels. Magura I spec ev adapter are not properly fitting. So still lots to do.

But damn I think it is starting to look nice.