Hello,

I am very close to ream the seat tube for the first time and there is one question for me.

The seat tube has got 30.5mm Inner diameter and the seat post with 30.9mm outer diameter

So there 0.2mm to ream, is that a normal amount of material to remove?

I have bought a adjustable reamer and would slowly work my way put to the desired 30,9mm diameter.

Thanks in advance,

Sebastian

1 Like

I would have the seat post at hand, to see/feel if it fits. And how much more you need to do

1 Like

If everything went accordingly, you would be left with a less than .4 mm wall, which is very thin. If there is any distortion in from welding or brazing it could be even thinner in places.

Your best options are a 30.6 seat post, or a seat post shim. The only 30.6 I’m aware of is a 0 set-back by Thomson. A shim for a 27.2 post would give you more options.

3 Likes

.5mm wall is not going to hold up regardless. Find a Thomson post that will fit with minimal cleanup and enjoy for as long as it lasts.

Or is this a lugged frame?

-Walt

2 Likes

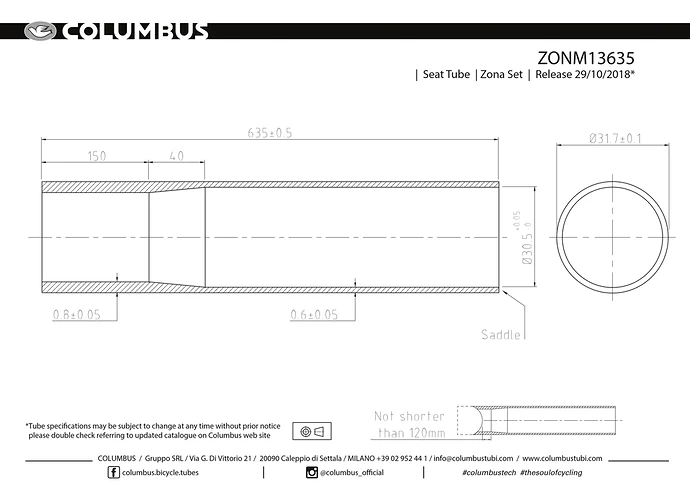

Those tubes are designed for use with a 30.6 seat post and only require a light clean up ream at most.

Fisik used to make a really nice 30.6 but stopped making it.

Same with WP Compositi, no longer made.

Thompson make a nice in line post. Im not fussed o their bent setback posts.

BBB make an inline post too. They are actually a vey high qality post and don’t cost much at all.

1 Like

That tube is meant for a 30.6 seat post.

Source: Have one in a bike I made a few years back, with a Thomson 30.6mm seat post.

1 Like

Hello,

Thank you for your answers!

I think I had the right feeling, that something is wrong with that wall thickness.

Unfortunately it is not a lugged frame

@DEVLINCC, perfect, I also found the sky scraper from BBB Cycling, so I will return the ritchey and go with this one.

For the next time, I am wiser and will take a different seat tube!

3 Likes

For fillet or TIG the minimum wall thickness I would use is 1.2mm.

Just fyi. Now go ride the darn thing and start planning your next one!

-Walt

5 Likes

You can use the same seat tube with an external sleeve which will strengthen that section or cut the top off the seat tube and splice in a thicker walled piece.

This is part of the learning experience.

4 Likes

Walt, only for the ST 1,2mm minimum thickness?

Yes I will do that, the material and a lot of learnt lessons are ready for the second frame!

@DEVLINCC, just to understand it 100%, the sleeve you mentioned at first, will be silver soldered over the ST? But afterwards welding the SS to the ST sleeve would be a problem, due to the melting of the silver solder.

The second option is to cut the Seat tube shorter and weld a thicker walled piece to it to get the final length?

You can TIG right over a silver brazed sleeve, it works fine as long as you’re moderately competent with the welding.

The entire seat cluster area should be at least 1.2mm wall (you can accomplish that by sleeving something thin if you’d like) extending below the seatstay and toptube joints. Otherwise expect failure down the road, generally from the seatstays cracking the seat tube.

Once you have a lot of experience you can go down to 1.1 or even 1.0 wall if you want to geek out on weight, but the handful of grams you’ll save is IMO not worth it. Failed seat clusters are almost impossible to repair.

Your existing frame, assuming you’ve already welded it, is not fixable, but it might ride ok for a while and you’ll have plenty of warning when it does fail (IMO).

-Walt

3 Likes

@Bastel_Mann Sorry to hear that, that is really frustrating. I feel like this tube simply should not exist anymore.

Also, thanks for everyone jumping in to help out.

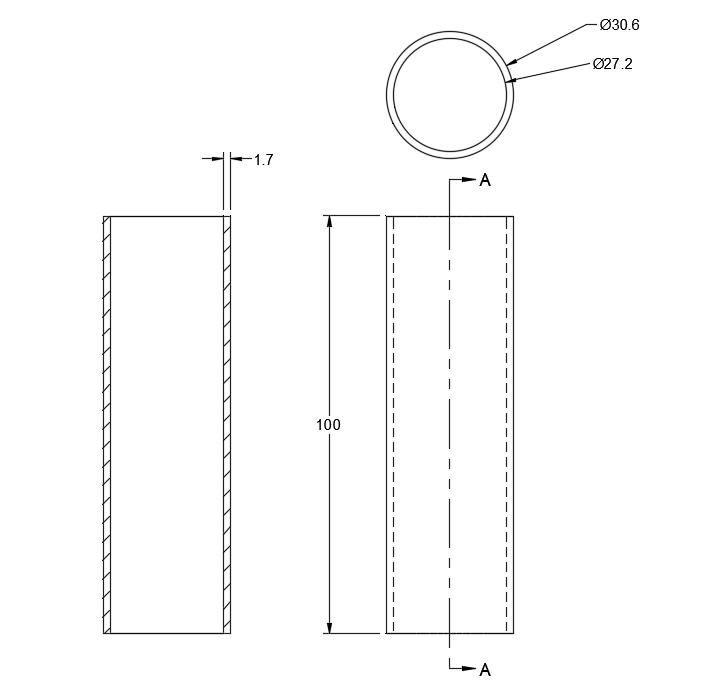

I have a suggestion, what if you went the opposite direction, and brazed in a sleeve on the inside for a 27.2 seatpost?

You could turn down the OD of a paragon topper:

https://www.paragonmachineworks.com/seat-collars/steel/steel-1-1-4-od-x-27-2-mm-id15-mm-step-relieved-id.html

That way you don’t have to buy a weird seatpost and live with the idea in the back of your mind that the ST might crack.

2 Likes

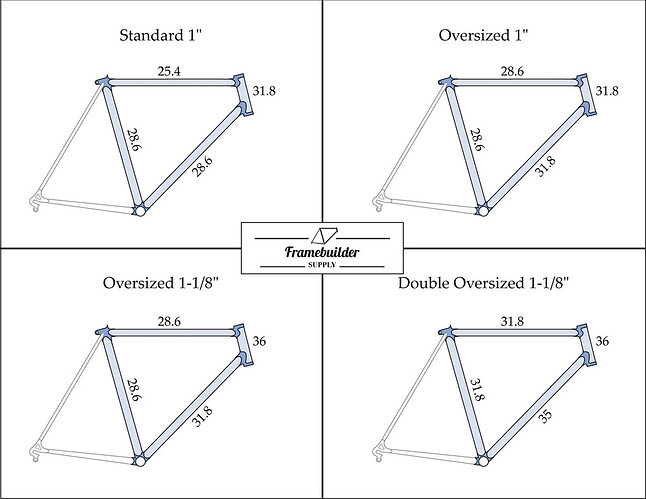

Its a tube meant to be used for lugs. It still exists because no one is going to retool everything for a different OD tube in their lugs. You can still get two really nice posts to suit, so everything still works for those wanting lugs.

Ah, thanks for the correction. I guess that also shows my confusion too  . For people learning framebuilding post-2020, lug frame knowledge is a dying art.

. For people learning framebuilding post-2020, lug frame knowledge is a dying art.

I did a bit of research and found this great diagram on framebuilding supply:

So it seems like this seat tube, seat post, and lug apply to the “double oversized” lugs?

2 Likes

Lugs are pretty neat and definitely something everyone should try once. I know Llewellyn lugs come in this double oversized size and Alex meade is developing a lower ht lug that will work with a Columbus tapered head tube.

1 Like

That would be pretty hard to pull off and get full silver penetration given that it’s already welded/distorted quite a bit. I guess you could ream, make a slip-fit plug for it, and maybe drill some tiny holes at various points to feed silver.

The problem is that usually you’d use a thicker sleeve and a thinner inner portion (whether sleeving a seat tube on a tig/fillet bike or doing a lugged bike), I tend to think even with some reinforcement the outer .5mm wall portion would end up cracking.

I’d probably just chalk it up to learning and try again personally.

-Walt

3 Likes

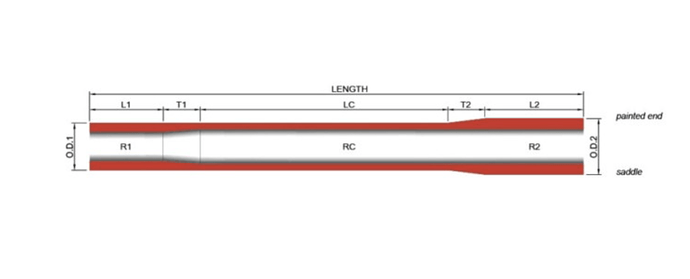

I had a look through the Columbus tube catalog and now I can see, that I have picked simply the wrong tube. Should have gone with something like that:

Since I am from Austria, it is pretty expensive to order stuff from overseas @Daniel_Y I will just ream that ST and order the 30.6mm seat post.

@anon91558591 as expected, everything is welded up and just waiting for the reaming

The first frame was a perfect training piece but there is so much room for improvements and I am really looking forward to implement them on my next frame=)

5 Likes

NO worries. We have all done something like this. Live and learn.

There’s going to be lots of other stuff you want to change/improve for frame 2 anyway.

-Walt

4 Likes

You could also get an aluminium shime and use a more common 27.2 seat post. You’ll get a little bit more give at the saddle for a smoother ride too, potentially.

@anon68659156 have been down that road with the lower lug of a tapered head tube. I don’t think I want to do that again. Crazy amount of work.

1 Like

Very nice! Lugs are a lot of work to begin with, did you make the lower head tube lug?

https://alexmeadetools.com/lower-head-lug-to-fit-tapered-columbus-head-tube/