Yep, Completely from scratch. I ended up sacrificing a tapered head tube to get the base part of the lug. It was frame number 6. So was still learning how to move metal around.

That aluminium shim is also a very sweet solution, because I could use the Ritchey seat post with set back.

Wow, your lug looks awesome, congrats on that! ![]()

Has anyone ever bonded in a shim with long term success? I have an older Niner sir9 that cracked at the seat tube (I believe this was a common failure since they did nothing to reinforce the seat tube in this area). It already took a 27.2 post but I ended up having a small 3” long section of 4130 turned down to 27.2 OD and 25.4 ID and bonding it into the frame with epoxy, after filling the crack with bronze. I then cut the slot to match the existing one. 25.4 post is flexy as hell but so far it’s held up as a fix I expected to be temporary to get a little more life out of the frame as a bike I only occasionally ride.

I’d assume it will crack again, but it sounds like it hasn’t so far, so awesome!

I mean, it had a “shim” (seatpost) in it when it cracked, too, right?

I’ve made external sleeve/gusset type repairs to cracked seat tubes before. It’s a huge PITA but it does work.

-Walt

If it’s an aluminium shim in a steel frame you could dip it in some salty water and pop it in. I’m sure it will be permanently bonded in fairly short order!

I did actually epoxy the aluminium seatpost shim into my wife’s Kona unit because it was annoying getting the slot lined up every time you adjusted the seatpost. It seems to have stuck just fine

I repaired one of those SIR9 frames with and external sleeve that I clam shelled and shaped it down around the top of the seat stays. Then silvered it all into place with fat fillets around the stays. That was 3 years ago and the dude said recently it’s going strong still.

No shim when it cracked. Was a 27.2 post, and I downsized my seatpost to fit in a steel shim with a 0.9mm ish wall thickness in addition to whatever the walls of the niner tube was. I assume you are right that I might fail again in the future but it seemed like the best way to attempt this with the tools I had at the time.

Sorry, I wasn’t clear. What I mean was that you had a seatpost in the frame when it cracked, and a seatpost, just like a shim, should theoretically support the tube. But it cracked anyway.

What you did is certainly worth a shot and hopefully it holds up!

-Walt

Really like this forum. Every time I have some doubts the topic is “hot”. Now I’m as well dealing with an externally butted (29,9) ST and find it quite difficult to find a seatpost for that.

That should take a 27.2.

-Walt

In theory - yes. But it;s pretty loose. Although - at the moment I have two of them and both are undersized. Or I’ve dropped my caliper one time to much. I was thinking about 27,4 but the only option is Thomson.

They shrink when you weld/braze them. 27.4 is a common ID to fit 27.2 after all is said and done.

A standard lugged seat tube, for example, is 28.6 x .9/.6, with the .6 at the top. 28.6-.6(2)=27.4

-Walt

Well, it’s already in place and the 27,2 seatpost slides loose till it reaches the tiny cauliflowers from welding (forgot to turn backpurge on after changing sides while welding…). I need to ream them and see what happens. It’s some kind of italian tube, but not columbus so I dont have any drawings of diameters/thickness, need to rely on my own measurements.

That’s normal. You should be good.

I’ll see that tomorrow. Today I’m trying to do some computer work. But keep posting here instead…

Another thing to keep in mind is the tolerance stack of your seatpost and your seat tube. Everything that is made has some variance in dimension. Even if everything is designed to spec, you can end up with an undersized seat tube and an oversized seat tube.

We were having some issues with dropper posts 31.6 seatposts slipping in our 35mm Fairing seat tubes. Turns out the batch of PNW we had were undersized ~31.5mm. Switching to the Tange seat tube mitigated the slipping issue. Using a 2 bolt seat clamp totally solved the slipping problem.

Hello,

Today I was on a mission, reamed the ST to 30,6mm ID.

Bought the right shim and used some EC2216 to bond it in.

I coated the seat post with PTFE spray so that the EC2216 doesn’t stick to it.

Then everything hardened and the seat post came right out after some wiggling.

Afterwards I split the ST and used the clamp to tighten the seatpost. It works perfect ![]()

Here are some pics of the procedure:

Hello ![]() ,

,

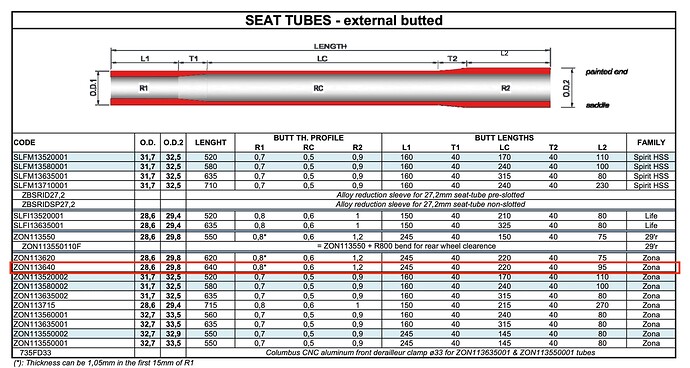

Since this frame is finished and I am sourcing material for the next one, the ST wall thickness issue popped up again.

Here in Europe it is easier for me to buy Columbus Tubi, so I would go for this one as @anon91558591 recommended min 1,2mm wall thickness.

But I do not get it, OD is 29,8mm, WT is 1,2mm so you end up with 27,4mm ID unreamed. What’s the next normal seat post OD you would use?

Or should I take the ZON113580002 then I would end up with 30,7mm OD unreamed and ream it to accepting a 30,9mm seat post? But then the wall thickness would the around 0,8mm after reaming.

27.4mm is the inner diameter of most seat tubes intended for 27.2mm seatposts. After brazing/welding the distortion from the heat will decrease the effective diameter so the post fits well.

Reaming a seat tube for a larger post than intended is a recipe for failure.

It’s not a size for size fit. You need to have a bit of ‘clearance’ so it doesn’t bind up when you try to move it. 0.2 over seat post size is normal. Issues come when seat post isn’t to spec.