Thanks! Feels a bit surreal to be featured on Pinkbike.

S&M Bikes have a video series called Factory Friday where they show a lot of cool stuff from their shop

Yo JimG! Thanks for posting the profile I wrote for The Radavist. I’m occasionally on this forum. Hope y’all have a great week.

I know this isn’t artisanal custom frame stuff, but I just had to share. The speed at which this guy fixtures and tacks a rear triangle is mind-blowing to me. I think the members of this community can appreciate the skills on display here.

Not really “seen around the web” but “seen around the world”. I am on vacation in Taiwan and had a chance to stop by ORA Engineering. I took the opportunity to ask some questions:

How they keep their flatmounts flat:

- Miter and weld on dropout

- Miter the first boss

- Weld in the first boss

- Miter the second boss (with Wire EDM!)

- Weld in the second boss

They said that this process, combined with their beefy fixture, gives them confidence in the flatness of their flatmount bosses. Welding the first boss (especially titanium) pulls in the chainstay, creating distortion. Separating the mitering and welding steps stops the error from propagating. Not sure why I didn’t think of that before!

Their mitering fixture (I think). First boss is already welded in:

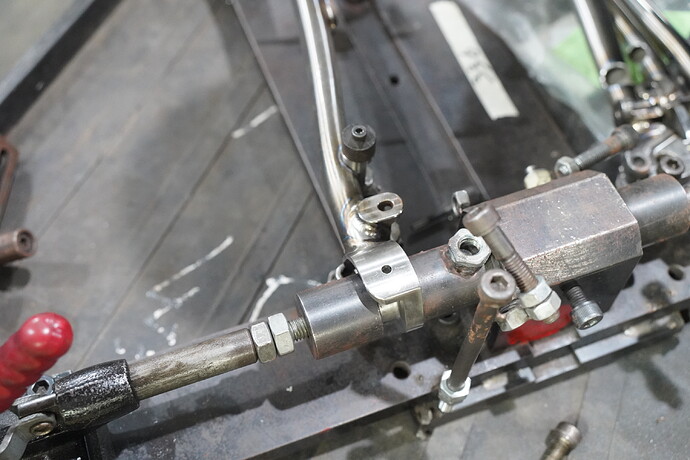

Their welding fixture:

Chainstay Dimples

There are to ways they do chainstay dimples. The first way uses a clamshell mold to dimple and bend/form the chainstay at the same time. The second way uses a pre-formed chainstay and added a dimple.

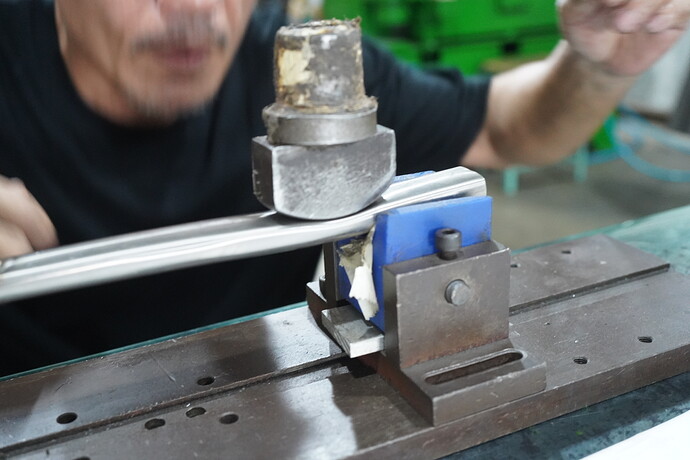

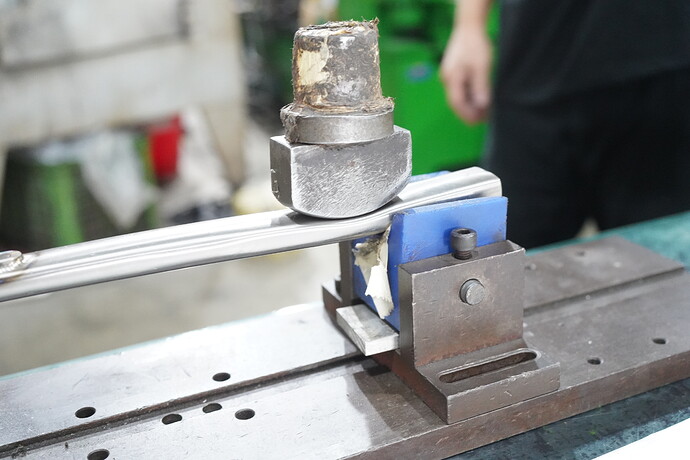

Mega Dimple Die. Notice how wide it is! The slight bend near the BB is also created during this process:

The chainstay is held in place with an adjustable fixture:

A key element were the pivoting blue blocks, made out of plastic. The shape of the blocks were “ovalish”. An exact match to the tube profile did not seem to be important. The pivoting allows the fixture to support different chainstay bends and “give” a tiny bit as the tube is dimpled. This prevents the tube from denting on the other side of the tube and creates a tiny bend (1-2deg?).

They told me the location of the die relative to the blue blocks was critical. There was an art to it (experience), but they try to put it on the edge of the blue block (as shown). This prevents the tube from denting on the other side.

Art = Skill = Hours of experience. There’s a certain amount of process that is difficult to quantify in small batches. Keep practicing, and when you’re done, practice some more!

Very cool!

I would have expected the dimpling die to go directly opposite the blue form. I would have expected this to leave a crease at the edge of the form

Very clever to do the brake mounts one at a time like that!

There’s still only one flatmount boss welded when they do the dimple. You should thing that the mitered hole will close up a bit when applying the force down on the tube

Seen on FB. Unsure if still available.

Gotta love the Bike Farmer!

Specialized has a really cool custom lugged bike on the DH worldcup scene. I saw this bike up close at sea otter, but I could never figure out what these holes were for:

I found the answer on this article thread (good read too):

Looks like it is an epoxy injection system:

Very cool! It’s a concept that can be implemented with 3D printed or cast lugs for bonding epoxy or silver brazing.

That’s real neat! I was considering building that sort of labyrinth into one of my 3DP lug designs.

That’s exactly what it is! It’s an labyrinth to ensure full epoxy coating. Injecting the epoxy in one port and squeeze until it comes out the second port

Some artisan builds from Europe!

The fork looks interesting - Cinelli is a brand that was able to resuscitate from its ashes, hopefully other italian brands can follow suit.

Interesting fork. It looks like it is a Hiride product:

Same company on the BMC Gravel bike!

A long (long!) time ago, I did a few forks using the internals of the Cannondale headshok. You could buy the forks used pretty cheap and they had a steel steerer. So you could dissasemble them and weld or braze new steel fork blades on to them while keeping the needle bearing suspension system. I’ll see if I can find some pics.