Long one for ya;

PPE is extremely important especially in your own shop space where no boss or safety inspector is holding you accountable. You only get one set of eyes/ears/lungs/fingers - protect them!

Welding/brazing fumes are bad for you. Metal particulates are bad for you. Sanding dust is bad for you. Solvents are bad for you. None of these things will kill you right off the bat but they are the things that can potentially shorten your life by 30 years if you don’t take them seriously.

Eyes: safety glasses at all times. I invested in a nice pair with anti-scratch and anti-fog lenses and I keep them on a string around my neck so I don’t misplace or forget about them. If you are doing a lot of mechanical grinding, a face shield is also a good option on top of your glasses. If you ever want to scare yourself straight on eye/face protection, just google angle grinder disc failure. Cheapie safety glasses are better than nothing but something shatter-proof is best.

For brazing I use shade 5 glasses. I personally find shade 3 not dark enough. The only issue with shade 5 is you can’t quite see the heat colour of the metal, so if you depend on that for a visual cue it might not work for you.

I have heard that glass-blowing didymium/purple tint glasses are quite good but have never tried them, and they are very expensive. You can get a cheap shade 5 glasses for $15-$30.

Lungs: minimum n95 most of the time working in the shop. Anytime grinding, filing, cutting metal you should be wearing one. Metal particulates and aluminum oxide/sanding dust is VERY bad for your lungs. Black snot at the end of the day indicates you are not wearing an appropriate respirator.

Welding/brazing: absolute minimum n95, preferably half face respirator with p100 cartridges. I am sometimes lazy about this because I find it uncomfortable and sweaty to wear for extended time, but I recently discovered there are high quality disposable p100 masks that are similar fit to the n95 style. I ordered a few to try out and will report back. They are more expensive (~$20 per vs ~$4 per n95) but the best PPE is the one you will wear properly all day over nothing.

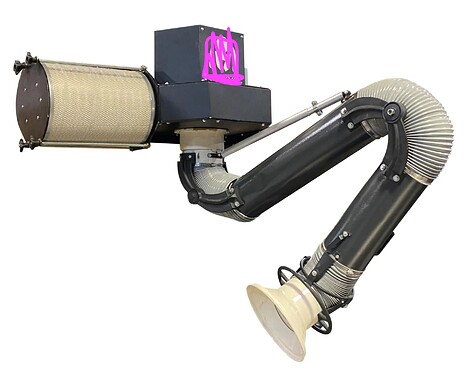

I use an in-line exhaust fan with a regular outlet plug as my main ventilation and I crack a window as my fresh air inlet (or open the door if it’s summer). They are relatively cheap, $200ish for something rated for 300 or 400CFM. Just make sure if you are buying one that it’s a plug-on version and not a hardwire version. The outlet is wired to a light switch so I can easily flick it on and off as needed.

The super cheap and easy version of this is buy a box fan and stick it in your window frame with the airflow pointed outside. Open another window or door as your fresh air inlet.

I would love to have a smoke-eater but they are expensive, loud, and take up a lot of real estate. You could diy a similar setup again with an inline exhaust fan and some flexible dryer vent.

Ears: any standard foam earplug will do. Earmuffs work but typically have a lower NRR than foam earplugs but are also easier to take on and off with dirty hands. I got custom in-earplugs made a few years ago which again was expensive but are very comfortable and I can wear for hours with no issue. Even low level db sustained noise can cause hearing damage over time.

Side note: you should never ever wear gloves when operating rotary equipment. It’s a good way to lose a finger or even break an arm. The weakest link will always fail first and in the chain of workpieces and machine tools if something goes wrong, your body parts are always the weakest link.

Unrelated to PPE but while we’re here; you should also never remove the guard from an angle grinder. If you are at a shop and they are asking you to complete work with a grinder that doesn’t have a guard, refuse it. You only get one set of fingers.

Other safety stuff: at least one fire extinguisher and fire blanket, eyewash station, first aid kit, and general first aid training are all things you should have. Even if working alone in your shed! Especially if working alone in your shed!