I did some tests with silver and also Fillet Pro. I didn’t have the confidence that either material would be strong enough for a chainstay yoke on an Enduro bike. I think your Y yoke would be just fine in silver or fillet pro, and I bet it would look amazing after being cleaned up.

Thanks for the feedback. I agree, the chainstay is a pretty high load for a silver-brazed joint. I have seen one of my early silver brazed yokes fail in shipping because a painter did not put the axle spacer in the rear, allowing for the frame to be crushed inwards. To be 100% clear, this is not a Neuhaus frame.

- the yoke and tubes were undamaged but the joint failed.

- It’s hard to read into that failure because no one knows how much it got crushed, and if it would have damaged other frames

- for reference, The yoke had an 8mm long internal sleeve

I think a brazed design could be viable if you printed very long and thin (.5mm tk) sleeves. But would it be as strong as TIG? I’m not sure. As I mentioned in the poddy, it would be great to have a test lab for framebuilders to answer these sorts of questions

My knowledge of the capabilities of 3d printing is quite thin, will chromoly ever be an option?

My guess is that oxidation (rust) of the powder would be a nightmare. However, I have no idea. There might be a simpler explanation: the industry has no demand for steel parts haha.

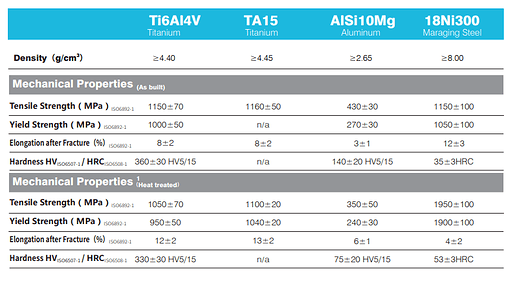

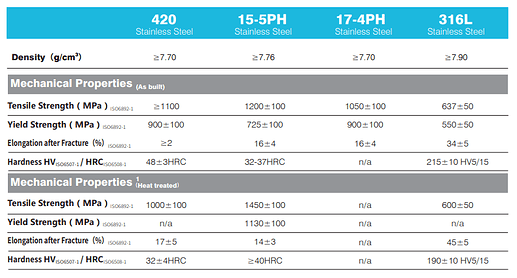

I attached a PDF of the mechanical properties I was given by one of our print partners. Because the printing process is so variable and geometry-dependent, I encourage everyone to do their own testing.

SLM- All in one .pdf (830.7 KB)