hey all, i have this old specialized rockhopper i modified. during finishing up the fillet brazing of the 9/8" head tube, it ended up twisting a little. the top of the ht is leaning towards the drive side of the frame a little bit.

i’ve watched a bunch of videos of frame straightening, but i don’t have a solid surface to be able to bend a bike frame on. i’ve been trying to brainstorm some solutions, going as far as welding up a jig of sorts to make use of my car’s hitch as it’s just about the only thing i have around that’s heavy enough that i could twist a frame with, but before i do anything like that i wanted to see if anyone’s used flame straightening to align the front triangle on a frame?

can i heat a spot on the top tube near the head tube on the side that’s “too long” and expect it to pull the top of the head tube towards the non-drive side as it cools?

I’ll start by saying anything other than replacing the headtube takes a bad situation and makes it ultimately worse for the frame. How much worse? I dunno. The right solution is cut the HT back out, clean up the brazing and try again. Heating/cold setting/straightening is likely going to add other stresses to the DT or wherever. On the flip side, you have probably not invested much $ into it so, why not.

Cold setting a twist will be difficult after it’s fully brazed. I don’t use heat to straighten a frame - “witch wanding” or whatever it’s called. There was a recent video of someone doing it to a rear triangle. A key aspect I saw in that video is constraining the frame once it’s heated and moved to the correct position. This prevents it returning to its original position as it cools. I haven’t ever tried this so I can’t say how effective it would be on your twist problem and you still need a pretty stout way to constrain the frame in the correct position as it cools. But what the heck! Go for it and let us know how you got along!

I had a slight twist in the headtube weird cargo bike I built as well. I tried heating tubes and twisting stuff, pulling on one tube and pushing on another with a bottle jack. I also tried heating part of one of the tubes and letting it cool like you said. Nothing worked, all that happened is the other tubes got bent around a little and the headtube stayed crooked. To be fair, mine is more complicated because its a weird cargo bike and the headtube is attached to the front of the frontloading “basket” by way of 3 tubes, not just 2. So I was more constrained in movement. All that to say, I think the only sure fix is cutting it out and put in a new one. You could definitely try twisting it, but you risk destroying the whole thing.

Worth the risk? I’d probably try it, I like weird stuff haha. Maybe take the ball off your hitch and bolt through the bottom bracket with the frame horizontal to the ground. Then strap the seattube to something crazy heavy or a lifting eye screwed into a tree stump or something like that? Then put a cheater bar through your headtube, heat up your ST and DT and twist?

I’m retired, my FB experience was all 30 years ago when tube diameters were smaller. But back then, taking out a twist was easy if you had a strong table with an extra-strong BB post. The bar we put through the head tube was about 1.5 m long and provided all the leverage we needed. With a jack under it to isolate twisting from bending. Since our tolerance for twist was very tight, I’d say we probably did at least a small adjustment on many frames, maybe even a majority of them. Partly because it was so easy, so why not?

I know some of you will say that’s proof that our tacking or brazing were faulty, because your frames always come out straight without needing any adjustment. But talk is cheap, let’s see your actual measurements — I doubt your frames come out substantially straighter than ours did. I’m talking sub-millimeter adjustments.

Does cold-setting make the frame more prone to fatigue? Maybe, but not in a big way. Frames I made in the '70s are still being ridden, so the effect can’t be much. They’ve had some big strong riders too like Natz champs, US World’s and Oly team members etc. Thousands of frames with a minuscule number of returns, mostly from crashing.

It’s true that today’s extra-large tube diameters and thinner walls often make this kind of cold-setting impossible without kinking a tube. Just one more reason I dislike OS tubes! I’m fully OK with being out of step with the rest of the world, but I’ve never liked the ride of any OS steel frame I’ve ridden. And I’m a clydesdale sprinter, so when I see light riders on OS I just cringe.

I’ve experimented with heat-straightening, but only for bringing the ST and DT into the centerplane (height off the table), not for twist. I think the concept is the same for twist, but I can’t tell you for sure, not having tried it. I chose not to adopt heat-straightening over cold-setting mainly because cold-setting is so much faster. You can’t see your results of heat-straightening until after the frame cools all the way down, impractical in production. But with large OS super thinwall tubes, heat may be your only choice.

Remember you have to constrain the thing being heated, keep it from going where it wants to go as it expands. Read up on heat-straightening (also called flame-straightening), an ancient technique with a huge amount of info out there. And practice on scraps or junk frames before trying it for real.

R+E Cycles in Seattle, makers of Rodriguez and Erickson frames, use heat-straightening, but the details are probably proprietary, so don’t expect them to hold your hand. I just mention this to point out that it’s being done with good results, they’ve been doing it since maybe the late '90s? Long time anyway. Method developed by their old FB Dennis Bushnell, who taught the current crew.

i’d really like to avoid replacing the ht on the bike if i can help it. the frame’s an early 90s specialized hard rock, so straight gauged seamed tubing, no buts, not oversized, nothing fancy.

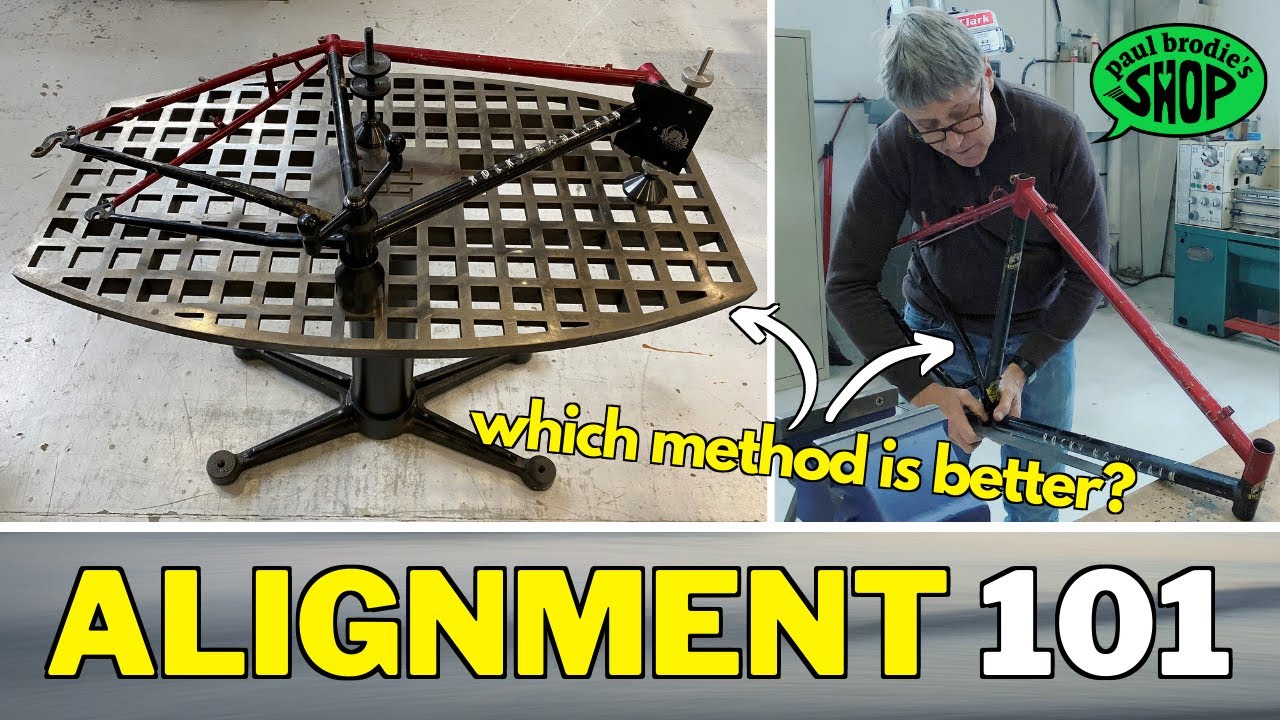

the ht isn’t super out of alignment, but it’s far enough that i’d like to try and straighten it. paul brodie cold sets front triangles during his frame alignments, he does it on an old rocky mountain of probably around the same vintage as the frame i’m working with in this video, including straightening the headtube to be in plane with the seat tube

problem is, i don’t have a surface table. i’m gonna have to come up with something tho, just pulled my 2nd frame out of the fixture and it’s off the exact same way about the exact same amount. ![]()

i also found an old welby post on another forum where he said he’s flame straightened frames before with success, but i’d have to rig something up to keep the frame from moving when applying heat, so either way i’m gonna have to get creative

Yes, but you’ll prob get more movement if you do the heating at the seat tube end. Doesn’t hurt to start from the HT end. Do you have a BB post you can fasten the frame on some surface? you cannot heat straighten unless the frame is supported against moving to the opposite direction.

You’ve prob seen my previous posts on the subject: 1 & 2

You can easily start with a straight piece of MDF or similar, you only need the table for references. Just turn a BB post on on a lathe or get someone do it for you.

My lowtech approach:

I fixed it?

thank you so much for posting this! the surface of my bench is mdf and i have been thinking about trying to use it for now, good to know that’s totally an option!

unfortunately i don’t have access to a lathe. i could potentially put a bolt through my work bench and use the bb cups from my frame fixture to secure the frame, the hard part would be making sure the “post” is perfectly perpendicular to the table surface. if i used wide, thick washers top and bottom of the mdf i feel like that’d keep it pretty perpendicular.

more stuff to ponder, thank you!

Nice! I see you don’t only use your table for reference, you use it for bending (cold setting) and as a welding table too!

So, no problem with the BB post, strength of how it mounts to the table? Impressive. I guess that large flange is key to how to make it strong enough.

This is how I used to do it before I started using heat instead of brute force ![]() Cold setting tigged frames is no joke. Although, I have two steel tables now. That BB post was turned by my dad’s mechanic friend from scrap parts. This one is fastened from the flange, but the new ones I’ve made myself, simply have a M20 bolt through the middle.

Cold setting tigged frames is no joke. Although, I have two steel tables now. That BB post was turned by my dad’s mechanic friend from scrap parts. This one is fastened from the flange, but the new ones I’ve made myself, simply have a M20 bolt through the middle.