Looks like a 61 degree headtube is in your future.

Time to try those slack head tube angles!

When that will happen to me, I will cry

Just trying to stock up the mis cut tubes bin! It was a silly mistake, new ones on the way, stuff happens sometimes haha

Time to bust out the tube stretcher.

Turn the saw blade around and cut it again? Maybe it’ll get longer?

Haha. I went the other way this time. I created a jig set up drawing that dimension my front center setting to the axle center instead of the jig pivot centre. The head tube arm pivots on the head tube center line. Ended up with a frame that was 30mm longer. ![]()

It is my enduro Jester platform and ended up with 510mm frame reach but with the custom 31mm stem it was only 10mm longer (in a direct measure) from the BB than my trail bike and it freakin rocks! I did a couple test rides and raced an enduro last Sunday. Pretty chunky terrain and it ate it up. Hit some doubles I had been scared of and easily cleared them all. Nearly ate it on a big step down though Landed very heavy on the front about 35-40 feet out and 10 feet down. I think my arse is still clenched from it. ![]() I’m still not sure how I survived.

I’m still not sure how I survived.

So big feck up in the frame with regard to intended design but awesome outcome luckily.

I got a two-fer! I built a brace and a shock mount, messed up a measurement, cut the brace out of the frame. So I come here to share and JUST NOW, I realize that I zigged where I should have zagged and that brace was in the right place the entire time. Coolcoolcool.

I can’t explain how glad I am to have realized that before I “fixed” it.

The fact that I can even put my own shoes on just amazes me some days.

At least I can just line it up with the original weld marks and tack it back in. I am not smart.

I was pretty sure the piggy back on my shock was gonna hit the bottom of the down tube under full compression. So I “fixed” it.

Oh yeah…

That’s the stuff…

Beautiful. 3" exhaust tube to the rescue…

Metal Pringles.

Perfect. Like it never happened. Chef’s kiss. 5 stars. 2 very enthusiastic thumbs up.

Here’s a fun one today. I designed a Retrotec-esque frame for my step dad. The fork was to be a segmented disc thing with 60mm offset.

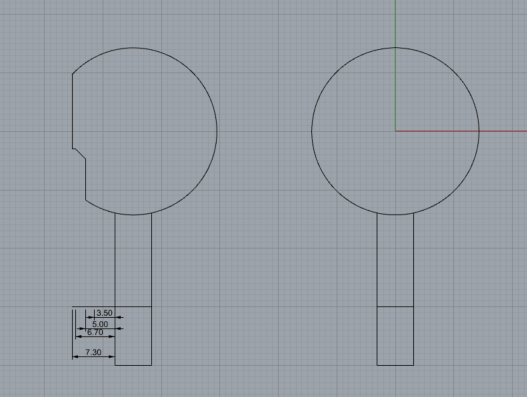

I modeled it up in Rhino. Had the drop outs cut. Welded it up yesterday. Looks good. I drop in the wheel only to find that the rotor hits the fork leg.

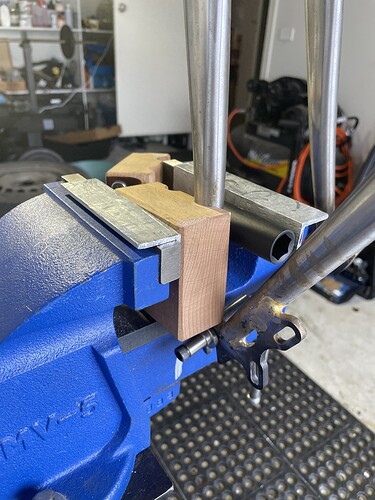

Top down view of things. Right side is what I have. Left side is what I’d need to make it work.

The funny thing is that when I was thinking through all of this I literally told myself, “Make sure to do a test fit with the rotor to make sure there’s no issues . . . before attaching the caliper mount.”

I dunno why it didn’t occur to me to draw it out in CAD too. ![]()

I’ve made this mistake before, a minute in CAD would have saved me weeks of heartache.

Is there any chance of saving the fork? Brakeless mtb? ![]()

A dimple in the fork?

It’s a lot to dimple. Something like 100 long and 10-12mm depth.

If I still had access to a mill I’d just take that material off and weld a plate back on but that’s still not entirely optimal. I’ll probably make a 650B or 26x2.5" coffee cruiser and use it for that.

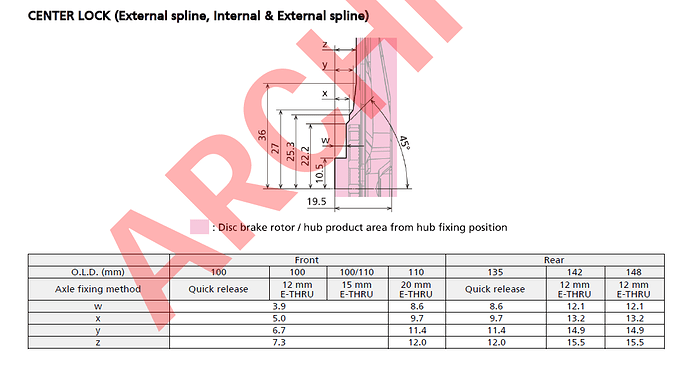

Pretty great lesson IMO. Here’s a screenshot from the Shimano page if anyone needs it. We’ve all seen the specs for the disc brake caliper mounts but this is about 6 pages later in the doc and (obviously) equally important.

I knowwwwww, but it’s rarely ever just a ‘minute’ for me. And really, after working at the computer all day, the absolute last thing I wanna do is more computer work.

The gamble sometimes doesn’t pay off:

I found a new and creative way of screwing up today. I brazed the seat tube and down tube 3mm off the centerline of the bottom bracket. Didn’t realize it until the main triangle was fully put together and wondered why the seat tube was askew of the head tube ![]()

![]()

![]()

I’m 100% sure my latest bike is quite off as well. I don’t really want to measure it to know how badly I messed it up so I’m just going to keep riding and try to forget it ever happened.

What you don’t measure can’t hurt you!

If this was for a personal bike, I’d just send it, but customer bikes are held to a higher standard ![]()

Do you know why it’s off? I would measure it and do some thorough RCA to determine exactly what led to that outcome.

In pretty sure that I didn’t tack it well enough before I pulled it out of the fixture. Then the DT-BB braze pulled it to one side. I get a little antsy when building and I have no patience whatsoever. First fillet frame but I like to learn the hard way.

You should measure it so you can be sure.

Take it slow until you have a consistent and repeatable process. If I could give myself advice when I built my first few frames it would be:

Take the time early on to develop a consistent process and don’t be in a rush to hold a finished bike-shaped-object. The development and reinforcement of good habits will speed things up long term.

Nicks comment makes me feel like I should clarify my images!

This was a frame I built up with tubes I had laying around, the goal was not to order new stuff. I knew disc clearance would be an issue. I guess that makes me extra silly ![]()

A crack in the top tube!

Perfect timing, as I found this while putting my new bike together. I had my suspicions, due to the progressive creaking my bike was making over the past week or so. Really enjoyed this bike, thanks for the fun times!

What led to this?!?

I think I went too light on the silver. The hole could easily be on the taper of the butt (I’ll cut it apart someday). I used no protective coating on the steel.