Now you can find it here: Where did DogFeather designs go?! - #50 by Daniel_Y

Besides @ChrisBlandford does anyone use a main tube mitering fixture.

What are you using?

Anyone have a design they want to share?

I use a Sputnik maintube fixture mounted to an 8" rotary table mounted to a Brown and Sharpe horizontal mill.

New miter jig.

Anyone else follow Soldura Motorsport / Kamfab on instagram? Sick brazing. And pretty solid miter setup: https://www.instagram.com/p/CxxizdkM9K-/?igshid=MzRlODBiNWFlZA==

I thought that was an on car brake lathe converted to a notcher ![]()

I have an automotive background and have watched brake lathes phase out of shops and sell cheap. I always thought they could be converted cheap. They are stiff, have loads of power and auto feed.

This is a prototype from @vogeltanz

It’s amazing. There is a linear encoder under the arm, so center to center lengths are accurate to absurd standards.

Hahn Rossman

@hahn_rossman are those going to be available?

I contacted vogeltanz about it, maybe 2 yrs ago.

I put in the order, than silence. I asked about it about 6 months later. Hé than asked what size miters I wanted and would get to it.

Unfortunately it never happened

I recently saw a video of a similar design:

RedBeard’s Garage Centurial tube notch kit

https://www.centurialinc.com/diy-tube-notcher-machine/diy-tube-notcher-stand-kit-pre-order

Other coping tools:

https://www.centurialinc.com/tube-coping-tools

I just received The Jeremywell tube notcher from Amazon. (similar available many places at differing prices) A step above the basic Harbor Freight (and others) notchers with needle bearing vs. brass bushing on the shaft. I hope it holds up and stays true.

The shaft is 1” vs. my old HF is 3/4”. It wore out and has a fair bit of wobble and is not really useful anymore.

Early impressions:

Has vertical adjustment, which may have uses for offset, but the “0” mark is not “0”. Easy enough to find and re-index.

The angle swing table attaches via a slot with a nut and an allen screw- which is too long. Was some wiggle until I cut the screw shorter. Again, easy enough fix.

The tube clamp is adjustable in/out, so a plus, but I’ll likely cut some 2” tube to be a sleeve to match the length of the backstop. (had I not opted for aluminum, I could’ve welded it on!)

I have some fine tooth hole saws from Metal-Guru, which look WAAY better than anything I’ve tried before.

On the road again for a few days, but will report back once I’ve mitered a few tubes.

If you’re planning on using a drill I would figure out a way to get more clamping force than that small arm will provide.

Out of curiosity what was the price. I have a similar design I’ve been meaning to make for a while now and have been trying to figure out what a reasonable expectation for cost is should I decide to sell a few to get the machining costs down.

$193 shipped. They have a steel version that was $10 less, I think. I’ve seen this design at Nothern Tool and others for a bit more.

And yes, I plan to make something to extend the clamp rather than just hitting the one little spot.

Follow up:

With the fine tooth hole saws from Metal-Guru this notcher worked well.

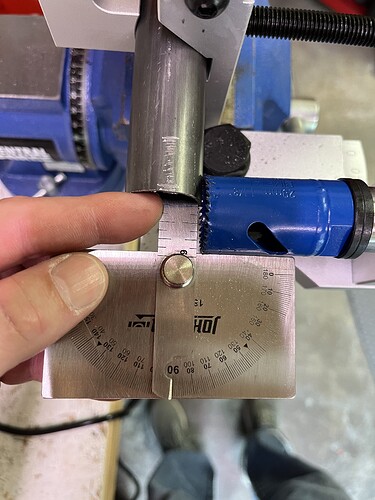

Verified the 0* mark was at 90* to the tube and went for it. Using a D-handle 9amp drill with a side handle and a speed-lock button (so I can have a good grip, steady feed, and let go if things go bad.)

I’m still considering a C-clamp with a V or angle full length for the clamp but the installed clamp seemed to work well on a shorter piece.

Fit up was good after some simple cleanup.

As an aside, the difference between the BigBoxStore hole saws and the fine tooth saws is phenomenal!

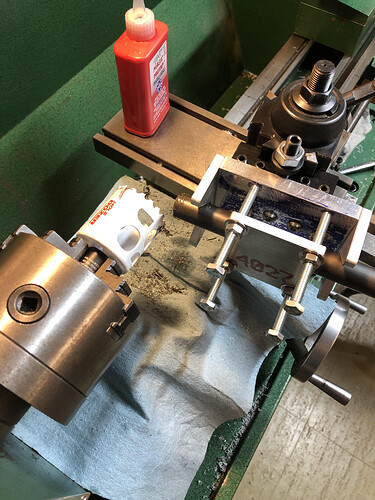

Resurrecting this thread a bit. If anyone is using a lathe for tube notching, I would be very interested in seeing your setups. Mainly, how the tube or tubes are mounted into the tool post. Thanks in advance.

@Johnmarmalade Showed a photo of his lathe mitering setup HERE.

Maybe we can get some more detail about the setup in this thread?

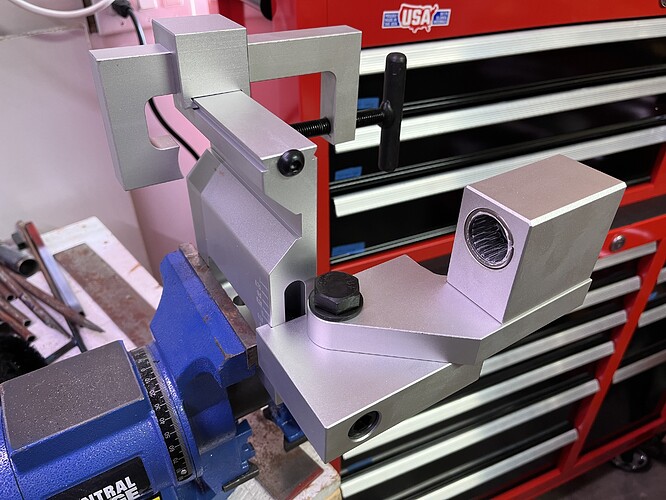

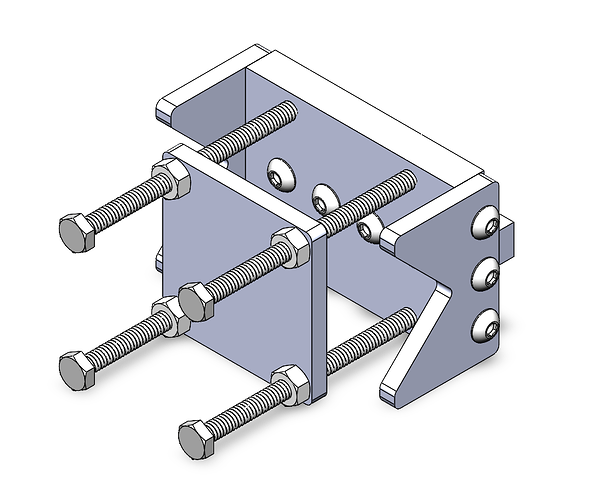

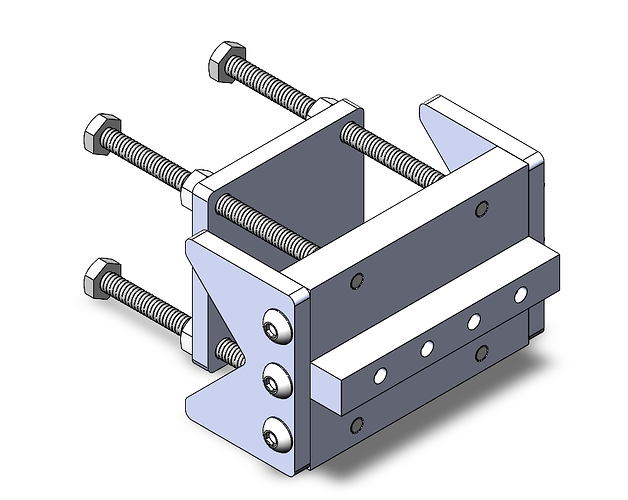

My setup is very rudimentary and there is lots of room for improvement. However, it is cheap (<$50) and is very easy to make if you have access to a mill.

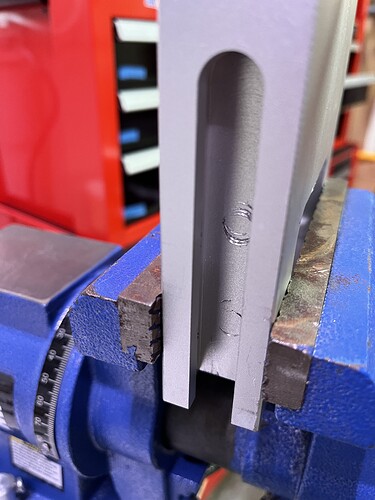

The back plate and tool holder clamp area were machined. The side plates and clamping plate I had plasma cut by Send Cut Send. The fasteners are all 1/4-20.

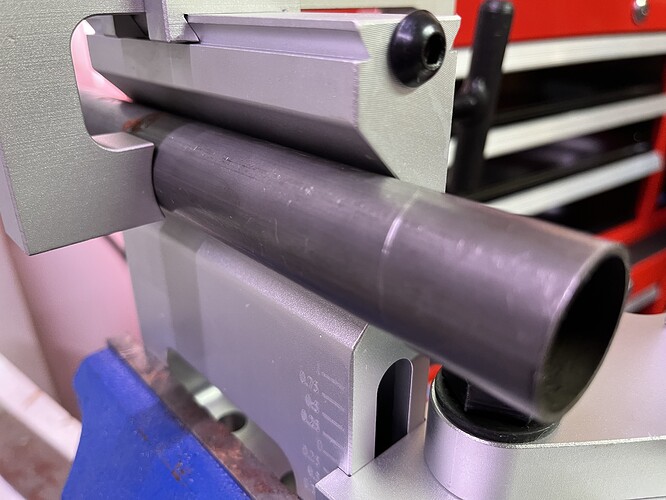

I’ve been able to notch tubes very slowly (a few minutes for a full cut, 30 seconds for a skim pass). Rigidity is the big thing holding it back. My small import lathe is the source of a lot of that. I plan to make a solid tool post at some point to replace my compound for notching. I also plan to replace the clamping screws/nuts with wing screws/nuts so I don’t need wrenches to secure a tube.

As I said before, it’s a very basic first iteration. If anyone is interested in improving the design or wants to re-create it I’d gladly share the files.

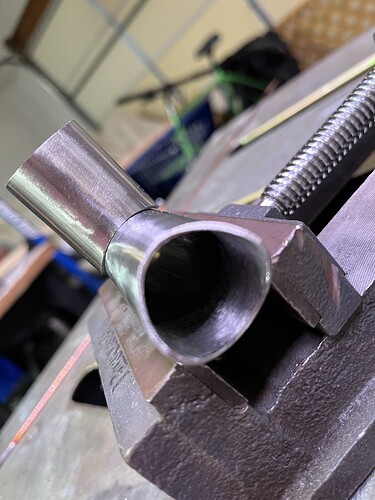

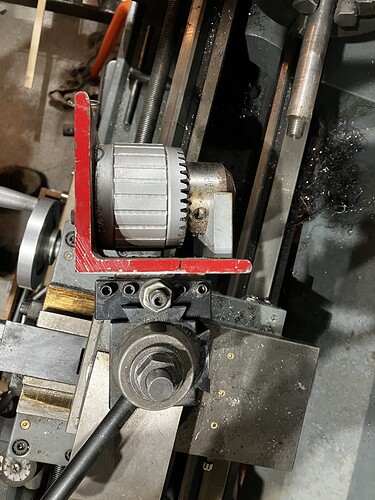

I have a setup made for smaller tubes. It’s made from a drill chuck that was used on a student project I made 20 years ago.

And I also made a second setup for larger tubes. Made from scrap angles I had laying around and c-vises.

Both are very ugly and lowtech, I know. But they work very well and are stiffer than the sync notcher that I still use too sometimes . The notches are much more clean.