BikeCAD Pro will export G-code for tube miters. See: bikecad.ca/cnc for more info.

Just saw the video from path less pedaled, pretty cool! I hope it can help bring on a new era of in-house bike shop built frames.

IMO the best way people can get more out of a bicycle is by going custom made. Made to measure frames are the future if you ask me.

What kind of price tag would a system like that be? Not that I will probably ever be in a situation where I could use one, just curious.

I saw the video as well, and it is super-cool, but mitring with paper templates and an angle grinder now probably takes me less time than setting that machine up would ![]()

Maybe nice for Ti though, which is what they were using it on.

I bet it doesn’t… ![]()

![]()

![]() Printing, cutting and setting up the template on the tube takes longer. we have been doing that for more than a decade… But anyway, we are now working mainly as B2B on small batches. The savings are huge and precision has increased.

Printing, cutting and setting up the template on the tube takes longer. we have been doing that for more than a decade… But anyway, we are now working mainly as B2B on small batches. The savings are huge and precision has increased.

As an example, one of our DT of a Gravel bike took 5 different setups and 5 different operations on our mill with hle saws and drills. We now do it in 1 setup and 1 operation. And we remove accumulated errors from switching setup to setup…

Yes setting up hole saws can be time-consuming. I’m saying doing it by hand is only a few minutes. Maybe I’ll time it on the next one ![]()

Yeah… but as I said, we work mainly on B2B on batches. Repetition is key here.

Ah I see yes, if you’re doing a whole batch the same, then it would make sense. But for custom frames you may have subtly different angles on each frame.

Well I just mitred a little bridge tube, and it took 3 minutes to cut and mitre both ends by hand ![]()

I agree that the Path Less Pedaled video somewhat overstated mitering times. However they were also lasering the seatpost compression slot and water bottle bosses and the combined savings are probably pretty good.

I know @hahn_rossman and Russ (path less pedaled) know each other and live nearby, I hope next time Russ brings Hahn along for framebuilding shop visits because I think we’ll get better questions from a fabricator’s perspective (nothing against Russ, he’s just not a framebuilder).

I haven’t finished it yet, but the Tritao video also shows some pretty interesting fabrication: https://www.youtube.com/watch?v=RIDAp_U6P18

I like how clean the e-bike at the start is. It see it as a modern/high-end take on the Faraday (RIP – but a good well integrated ebike company from a decade or so ago).

Yes that e-bike was beautiful. Using the almost invisible Mahle system you can also now get from Reynolds as a small builder.

For instance, on DT we have replaced a 5 setup and 5 operation (DT-HT Mitre, ST-BB mitre, DT-ST mitre, above and below water bottles) with a 1 setup and 1 operation. This is time saving while increasing precision. And after the code is done (quite fast with our software) we can repeat it when we need without any more calculations.

Yes DT has the most operations. The one mitre that is more or less impossible to do by hand (I find anyway) is unicrown fork blades. Because the tube is curved, you can’t wrap the paper template around it!

There is one mitre which is impossible to do with a hole-saw, and that’s DT into tapered HT. This works very well with paper and would also be nicely done by your laser.

Mitering a downtube to a tapered headtube with a hole saw is far from impossible. There are a few ways to approach it, some are very reliably repeatable

So how do you do it? You obviously can’t use a tapered hole-saw. Cut some of the way through from each end with different sized hole-saws and then interpolate between them with a file?

Check out this post from Daniel - Tapered Headtube Secrets: how to slay the tapered headtube

That’s really interesting! I make the error more like 2mm though (but I may well have worked it out wrong).

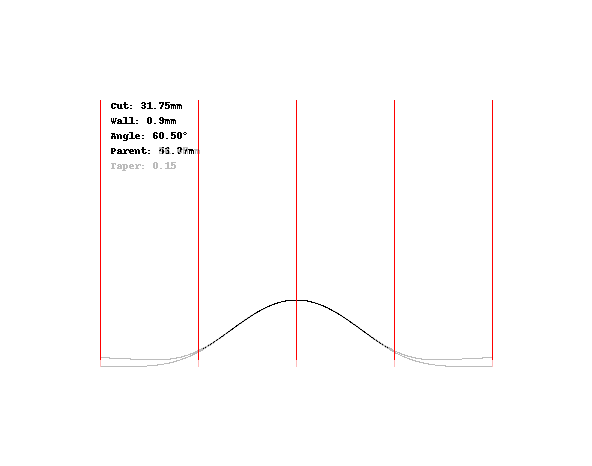

This is a template for a “0.15 taper” (by which I mean the ratio of diameter to length change-- in the case of a Columbus tapered HT you gain about 10mm over 64mm of length) superposed over that for if you had a 51.78mm HT (which is my estimate of “theta*” in this case).

The image is at a resolution of 100px per inch, and I make the discrepancy 9 pixels at the edges, which is 2.29mm.

But the good news is that the one based on 51.78 is the one that’s too big. So you could easily adjust it.