For the past few months, I have been thinking of doing a build log for my first build but have been so busy with my thesis and work that I haven’t had time for it. I also thought that if I don’t have time for regular updates, it isn’t worth it. Now I decided it is time to post it even though I don’t have the perfect photos or the perfect summary of my project. So here we go.

The purpose of the project was to get familiar with different manufacturing methods and to get some hands-on experience of machining. I also made my thesis from this project.

The front triangle is made of machined lugs and carbon tubes, but I will start the build log with the rear triangle as that is currently being manufactured. The rear triangle will be machined from 7075-T6, and it will be based on a high pivot horst link design. The kinematics are highly inspired by Kavenz vhp so all the credit to Giaco and everyone else from Kavenz! Seat stay will be a separate part from the dropouts to get some adjustability with changing the dropouts and maybe to tune the stiffness of the seat stay, who knows.

Dropouts are UDH compatible, and the brake mount is removable. The rocker will be made of two halves that are connected currently with bolts, but gluing is also a possibility. That’s a very brief introduction but I guess it’s better than nothing! I’m sure I forgot something.

I have no prior experience in CNC machining, so it’s been a bit of progress. Hoping to have the first prototype ready by the end of the year and I hope I have time to do some follow up posts soon!

Here’s some pictures I have taken, I probably should take better ones if I start to post more of these.

Render of the rear triangle

First usable (I hope so) D side dropout

Same with the N side + the brake mount

Brake mount after first op

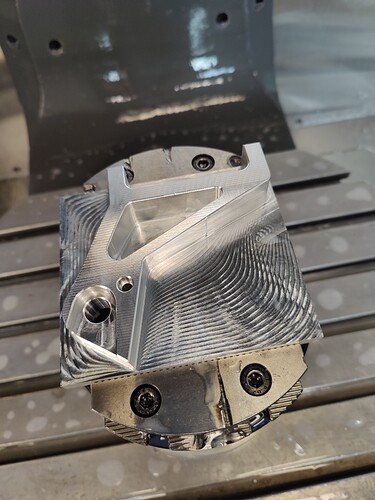

Half of the rocker after first op.

Surface finish on the rocker

Cheers, Jere