Told you I’d be easy! ![]()

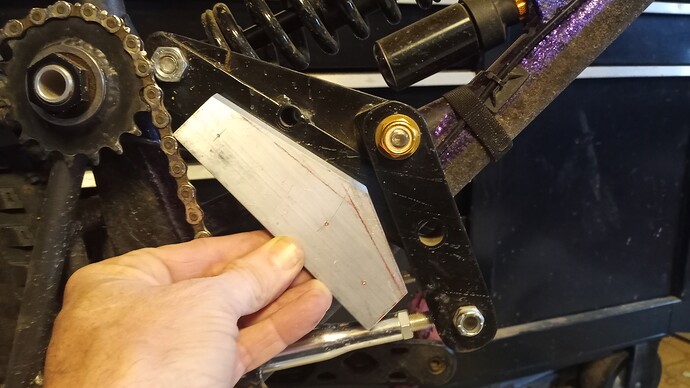

I’ve been putting off making the linkage parts because for some reason I thought it was gonna suck way more than it actually did. The rocker link is just gonna be 2 pieces of this 3/8" (10mm in mountain bike terms) aluminum. Here’s a size comparison between the new link and the current deal. New link much more smaller.

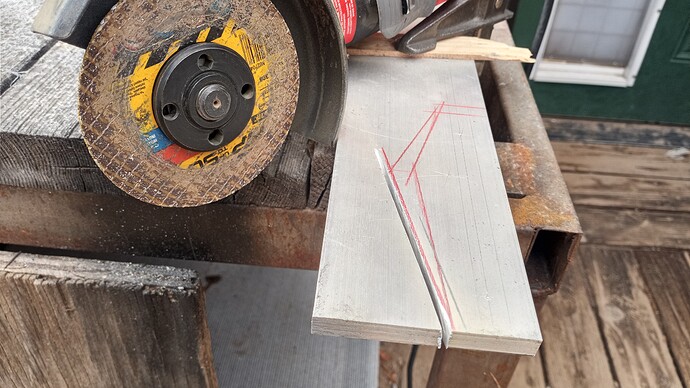

Anyone who says you can’t cut 3/8 aluminum with an angle grinder and a cut off wheel just isn’t trying hard enough.

The “through-the-seat-tube pull link thingy” is a 4130 swedged tube with a 5/8-18, 7075 aluminum rod end in it. The piece of 5/8" that goes through it has a .063" wall to take a 1/2 od bushing for 3/8 hardware.

The power of bike compels you

Shit, sorry, it’s supposed to go this way

That’s better

It’ll end up going in there a little something like this

It’s gonna get trimmed, i hope that’s really obvious. That keeps a little bit of adjustability. You know how we say around here,

“If you can’t make it right, make it adjustable”

Today’s episode of “Why. Just why?” brought to you by hubris, the sunk cost fallacy, a crushing desire to be liked and the letter M.

More fiberglass

Holy shit! It’s a thing! A thing I can hold in my stupid hands!

Let’s check our tire clearance…

Fuck.

So, the axle is crooked and that drive side seat stay needs to be moved out by about 4mm for reasons.

But other than that, Mrs Lincoln, how was the play?!

Double fuck.

Swear to god, if I didn’t have to also fill my argon bottle AND buy the steel parts for the rear end, this styrofoam bullshit would be in the fuck-it bucket so fast.

At least it looks like my adjusty rod-end will clear the tire if I ever get that far. Silver linings and all that.

Okey dokey, I’m gonna go chop this shit into pieces again. Fuck.

Hi. I think your main fault is construction based on slender beams. For stiffness it is better to create shapes with bigger volume. Look for similar carbon parts from well know brands. And…bigger volume part from blue foam is much more simple for sanding and mainly laminating. Also sharp edges is hard for laminating. Sharp edge is place for crack in the future.

Your unsuccessful creations bring to you experience. Learn from it and you will be successful.

Deleted post

Hi! My misalignment wans’t due to a lack of stiffness, it was simply misaligned. I also forgot to take a taper into account when I landed the ds seat stay lower than the nds. The foolish thing is actually surprisingly stiff at this point, I had a hard time pushing th tire into alignment by hand. Some clever guy suggested fiberglassing the individual pieces and it worked pretty well.

Right, like these https://www.rockwestcomposites.com/45235 I have looked at commercial available offerings, I’m even going to steal their layup and proabably add a few layers. Mine will also be larger than these in every dimension and have a thicker wall.

Also, as far as the “slender beams” and sharp edges…you get that I’m not finished yet, right? I was doing a test fit before I went further. If I plan to add several millimeters of glass and carbon, I kinda have to start with something smaller than I want the finished product to be. I’m hoping for a finished dimension of approx 1" x 3/4" or 25 x19 for you metric types, so I started with 13x19 assuming I’ll add around 3mm in every dimension at a mininum. I’m also gonna glass in all the sharp transitions so everything is nice and smooth. I’m definitely not an engineer, but I think that’s gonna be plenty robust.

And as soon as it breaks, I’m replacing it with a steel version so…

I just kinda want to get it done at this point.

Learning sucks and expensive. But better you the me. ![]()

It can. However, as long as I learned something, it hasn’t been a wasted experience.

On that note, I went ahead and ordered steel parts. I can still continue on the carbon fiber if I want to, but let’s be serious, the first attempt is always the first attempt. I’m gonna break it, I know I am. I expect that and am comfortable with it. That’s part of the process…

If I know I’m gonna break it and I know I want to build a steel rear end when that happens, I’m gonna skip the middle parts where I’m just pissed off at it all the time and jump to the fun parts again. This is supposed to be fun. Goddamnit. I’m not trying to be the carbon bicycle guy. I’d much rather be the riding bicycle guy.

Maybe if I lived in a place with fewer rocks I’d be feeling more positive but I really can’t help feeling that I’m spending waaaay too much money and time building a part that is more complex and ultimately less durable than the alternative. Lighter? Sure. Cooler? Maybe. I’m not very concerned with weight and I think unbroken shit is cooler than broken shit any day.

Don’t cling to a mistake just because you spent a long time making it.

I’m excited about this project again. Lets build a damn bike!

I was watching somebody’s youtube the other day (I honestly don’t remember) they were building a steel full bouncer for their buddy to go racing. I heard my self say “I miss building bikes” I feel like I’ve been trying to learn composites so I can impress the engineers and rocket surgeons and kinda lost the whole point.

Anyhoo…I started playing with steel again today and it’s fucking awesome!

But I need your help.

As smarter people before me have done, I’m gonna build this whole rear triangle out of chainstays. Stiffness being the primary goal. But! I don’t have a shitload of room between the chainring and everything going on right there (imagine!) and in my visualization today I realized I could buy some clearance if I elevated the actual chainstay a little.

Problem being, I also want to drop the “seat” stay for chain clearance and there’s only 150mm between the bb and the main pivot.

Forgive the shit picture, I’m just trying to get an idea

Those stays would be awfully close together…

Fuck it, what if we just yolo this whole thing and do this?

We get all the clearance, it looks harder than a coffin nail and I don’t recall ever seeing it done that way. That connector piece is streamline tube from the airplane store, it’s .045" so plenty enough, add a few gussets and Robert’s your father’s bother?

The opposite side will get a more conventional layout.

It’s fun to be building bikes again.

What do you think?

The smaller the angle between ss and cs the more you will load them. So if the nds is more conventional this might lead to some twisting deeper into the travel. Also structurally less than desirable. Could you route the chain underneath the ss? Might look a little strange though.

Makes me think of the ancillotti dh bike:

Other than that you should totally consider a cabron fiber rear triangle. That would give you a lot more design freedom ![]()

Good old brooklyn machine works!

In November I had a chat with Doc while in SLC. The good old days.

The fact that people always bring up BMW and the like when looking at my garbage just makes my heart happy. No lie, that may have influenced me a little bit when I considered putting the chainstays this way. Also the second ancillotti comparison, which I also enjoy.

If this bike building shit doesn’t pan out, you should consider comedy. The world needs more funny engineers ![]() You figure if I make one sid ethis way, I should make the other to match? I see where that would make sense. I was thinking that having the other side more triangle-y would help brace it more and twist less but I’m sooo not an engineer, I’m not even funny.

You figure if I make one sid ethis way, I should make the other to match? I see where that would make sense. I was thinking that having the other side more triangle-y would help brace it more and twist less but I’m sooo not an engineer, I’m not even funny.

I was thinking about something similar for the next park bike build, now I’m imagining each side made from a pair of chainstays and I really don’t hate it.

Since “not ideal” is my bread and butter, I decided I was going this way. There’s so much room for activities! I’ve got some .080" 4130 I’ll be using to make gussets, I’ll put tube gussets where I can.

I dare this to not work.

Man, actually building bikes is really good, waaay gooder than sanding bikes. It’s nice to be able to put some music on and work for an hour or so and see real progress, rather than just getting itchy.

I’m liking the way this is coming together, I put the ass in asymetrical. It’s got plates and gussets and shit everywhere, there’s even a little aero tubing for airplanes in there. All the little gussets are getting tig brazed in with silly bronze. Ideal? Probably not. Gonna do it anyway.

I think it looks like proper race car shit.

If you squint, you might be able to see my little shop sausage in his little helper house.

Speaking of racecar shit, I did something kinda dumb and awesome.

'31 ford deluxe coupe. Sausage apporved. It’s gonna be a good year.

Ruby pink base coat, ruby pink flake .008 & .015, just a pinch of multi size silver for sparkle and a dash of Starlight for a little prismatic bling. ![]()

#themostmasculinepaintjobimaginable

Accidentially matching Pit Vipers for the win

What are you planning for the Ford? Resto or rod? (I think I already know…)

You’re going to be hearing from my lawyer, those photos damaged my retinas and now all I can see are pink sparkles ![]()