Since I’m horrible at keeping notes and figured this may be a useful resource for others in the future, I’m going to log my initial experiences with working with titanium here.

I bought a titanium advanced kit from Joe at the Philly bike expo which is a great deal. Advance Level Kits - Titanium Joe

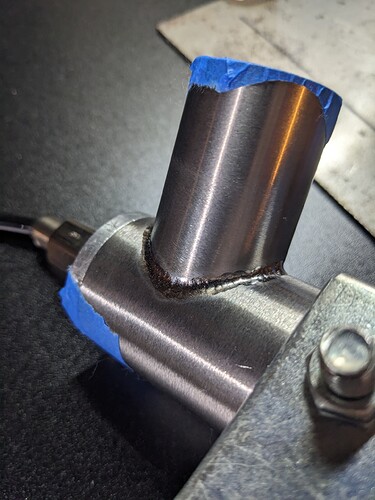

Test joint #1, 1.25" .028 wall to 1.5" .125" wall. I figured why not start with the largest wall thickness differential

Weld setup: Furick BBW kit from weldmetalsonline, 16 cup 3/32 tungsten. I noticed too late that I probably should be using a smaller tungsten, but it seemed to work ok 17/18/26 Stubby TIG Torch Kit for Stainless Steel

Tube prep: Sanded inside and out with 120 grit, then bathed in acetone. Need to wire wheel after sanding in the future, the surface was pulling out fibers from the microfiber towels.

Back purge 10CFH, torch 25CFH 8 sec post flow. 2 fusion tacks straight current @50amps, did not need nearly that much amperage

Fusion pass: (1Pulse/sec 30% on time 5% background @120amps), I was blown away by how nicely the metal melts down and sticks together. I don’t think I could ever fusion weld this thin of a tube in steel, but it seemed to work just fine with titanium. I was able to do most of the joint without filler, but keyholed when the intersection started to get tight so I used the .035 rod to fill on the “saddles” of the miter. I think someone with more skill than I could do a fusion pass without filler, but it seems like ti is more picky with torch angle than steel. I noticed when the torch angle isn’t perfect the rod will stick like everyone talks about, so the material definitely lets you know when youre off. Also noticed that you need a lot less amperage than steel to form a puddle. I was hardly stepping on the pedal on any of the stitches. Surprisingly I didn’t end up with any color and was able to fill the hole I made.

Filler pass was straightforward, easier than usual since there is already a seal between the two tubes. I used the .045 rod that came with the kit and it turned out ok. Not the prettiest but i’ll take it for now. Probably got lucky and ended up with minimal color on the outside, on the inside there was a small section that had some blue/gold but nothing terrible. That’s all for now, sorry for the lengthy post.

My questions for others:

Do you use different hole saws and or hand files for titanium?

What’s the heat tape of choice for sealing off ports and such?