Nawp, not yet ![]()

Product Information:

OD: 1-3/4"

Flange Width: 1.180"

Materials: 6/4 titanium (1018 steel version will be available at a later date)

Compatibility: SRAM UDH/T T-type; meets all SRAM specs

Weight: 86 grams

Alignment: Symmetric

Options:

-

Fixed (no bushing)

-

Eccentric, uses a 0 mm, 0.5 mm or 1.0 mm offset bushing:

0 mm: no external markings

0.5 mm: four 2.2 mm radial holes on the flange

1.0 mm: four 2.2 mm radial holes on the flange and a single identification groove on the 24 mm diameter

The bushing must be welded in and once installed, is not meant to be consumer serviced.

Directions for eccentric installation:

- Fixture with the 0 offset bushing.

- Fit the wheel after fabrication and switch to an offset bushing if needed.

- Use a 2 mm or 5/64" hex key to rotate the bushing, using the radial holes on the flange.

More information:

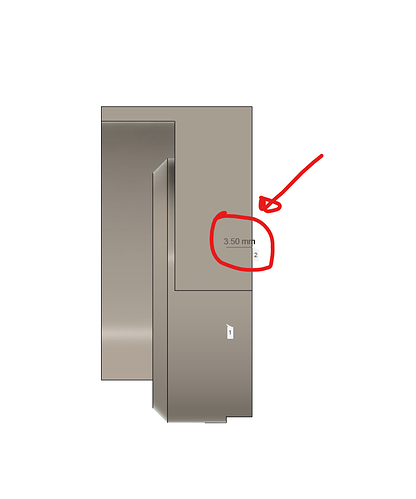

The chainstay center MUST be 3.5 mm above axle center to meet SRAM's specs.

Flange width is as wide as possible without violating SRAM's clearance mask.

There is about 3 mm per side to make the weld with 7/8" chainstays and 3/4" seatstays.

Push the seatstay outboard as far as possible to avoid SRAM's clearance mask.

For flat mount:

Because the chainstays are raised 3.5 mm above axle center line, a 160 mm flat mount is required.

For a straight seatstay do not go less than 60 degrees between the chainstays and seatstays.

For post mount:

Our BK0017 or BK0018 will work, but it lands half way on the DO hood; a revised brake mount is in process.

Use the flats on the bottom of the dropout to index:

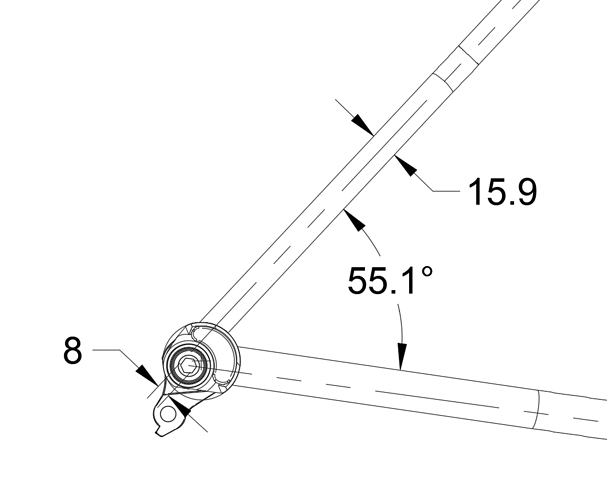

Put a straight edge on the flat and aim it 16.5 +/- 3 mm below bottom bracket center.

Dummy axles are available for purchase.

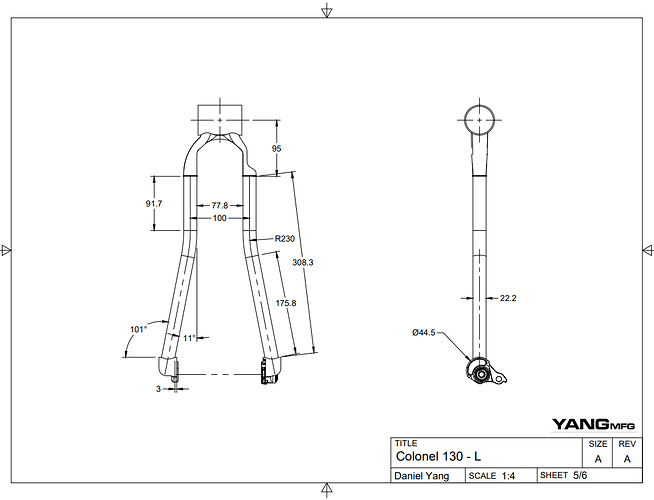

FYI here are some CAD designs with the dropout in a mountain bike, looks pretty good!

A few notes:

you will want to offset the CS ~3mm above the dropout center to get clear the T-type spec and make space for a 22.2 chainstay

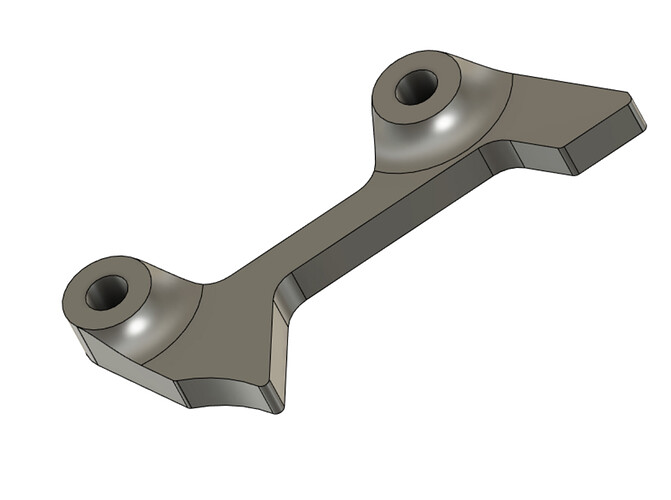

Here is a brake tab design I cooked up. We will laser-cut it as backup, but hopefully, PMW will have something CNC’ed in time for MADE!

Looks great, and we will have a CNC brake mount for you!

See our eccentric UDH/T-Type in action…

https://www.instagram.com/reel/CvQCjgUvzdh/?utm_source=ig_web_copy_link&igshid=MzRlODBiNWFlZA==

Both PDF and STEP files are available online

Hi, I’m clearly late to this party! I just bought a set of these Allotec C82 dropouts to use on an upcoming build. The problem I just realized is that the left side dropout has a 19.4mm width and my indexed dummy axle is 20mm in width. (I think the B and C measurements may be switched in the above diagram) What kind of dummy axle and/or dummy axle adapters are people using to use these dropouts? From what I can tell, the Paragon FT1162: UDH Adapter for Dummy Axle Indexer is 20mm in width.

I used the PMW UDH adapter with a 148mm non-indexed dummy axle (like PMW FT1124). You just have to manually align the DS & NDS dropouts which isn’t too bad.

Have to chime in here… Our FT1162 will fit only our dummy axle spacers for use with dropouts made here in our shop. We can’t say if our tools will work with dropouts made by other like IRD or Allotec.

Right, it is 20 mm.

Here’s more on UDH/dummy axles:

UDH Dummy Axles are an ongoing evolution. We do have two series of dummy axles, they’re on the website as 19 and 20 mm. 20 mm fit our dropouts, and some others. 19 mm is the actual dimension from Shimano, which we didn’t have when we designed our first dropouts.

19.4 mm is an odd size that will work with any hub, but is a PITA relative to dummy axles. FT1162 will work to space the right side dropout 7 mm further outboard, but it will not index dropouts with symmetric axle slots. We made this as an interim fix to get our UDH right side to work with our existing BoBI left side. Unfortunately, this has been a source of confusion.

As @liberationfab mentioned, FT1162 will work when used with a spacer (no indexing features), but the dropouts must be indexed externally. This can be visual or mechanical. Our latest UDH dropout (DR0072, DR0073 and DR2073), the @Lichen_precision UDH V2, and the @WHilgenberg Fastback have external flats for indexing. There are probably others out there, but I haven’t looked.

I think external indexing features are a much better way to index rather than using the axle slots. As many builders have found out, axle slots vary greatly in size and whether or not the sides are parallel or not. The added advantage is that spacers are cheaper than indexers, and are (relatively) easy to make on a decent lathe. We will soon have a UDH-specific spacer for the right side that will use any 12 mm spacer and put the right side dropout the correct 7 mm further outboard. It’s a simple lathe piece, so it will be inexpensive.

We also have dedicated UDH dummy axle spacers, but we’re currently out of stock of 142 and 148 sizes. These are probably the best long-term solution for alignment and ease of use.

Stay tuned for for more developments!

These DR2072 and DR2073 dropouts are ready for the next update of BikeCAD.

Thank you all for your replies @liberationfab, @Coco_PMW, @mark_pmw, and the time you took to send them. I won’t be starting to build this frame for maybe another month. I’ll pick up a PMW FT1162 in the meantime and hopefully you’ll have the FT1122 in stock by the time I need it and am ordering other pieces from you. If not I’ll have to try making my own dummy axle!

Thanks again, much appreciation!

For anyone using the C82 dropout, what axle are you using? It looks like the ideal length would be 177mm or so. I’m not thrilled with the thread engagement of the 173mm PMW axle but it seems fine for now.

The Wheels Mfg RTA-12-175-1.0 seems like a viable replacement for a bit more assurance.

All of our dropouts are 8 mm thick on the left (NDS) at the the hub/skewer interface. Looks like the C82 is plenty thick there, and could be cut down to 8 mm to use our skewer. It could also be cut down to accommodate a lot of other skewers, but I’m in favor of 8 mm!

That seems pretty reasonable! I gotta see how hard it’ll be to throw this frame in the mill ![]()

Hi all,

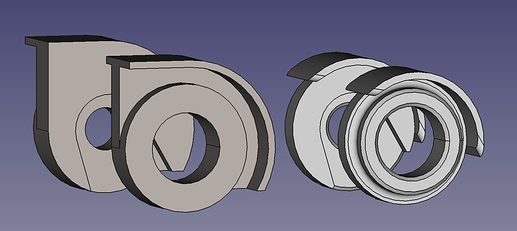

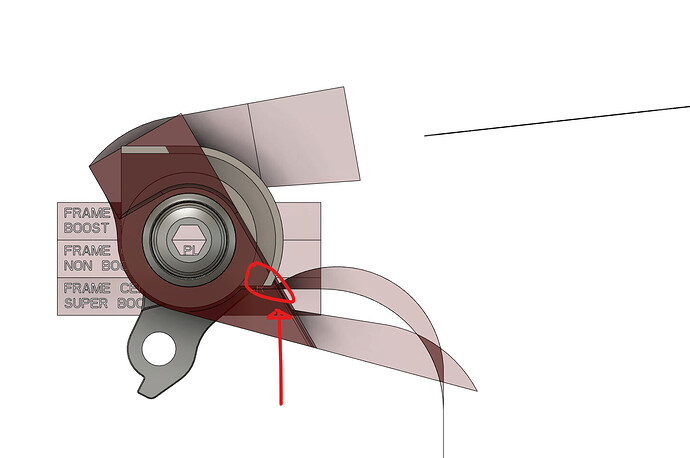

Not sure are this conversation about the aesthetic style is still going—and lately I play around with some symmetric design hooded style with the guide of SRAM UDH step files

There’s 2 model (“teardrop” D shaped and round) with 20mm hood. The D shape one jumbo 50mm diameter:(. If you guys want to jump down the check the stay and flatmount clearance would really appreciated—STEP files in my google drive as follow

https://drive.google.com/drive/folders/1XgZGSb7nP53cepXS_Y55598brUB5vbAp?usp=sharing

Thanks!

(sorry for untidy design and broken vertex due to my freecad not works properly on M1 mac, also this my first chance designing something like this with CAD software)

Thanks for putting this out!

We have invested a LOT of time in our current design, so unless we find a flaw, we’ll stick with it.

We can check your design with the mask, but it may take some time. Anyone else out there want to verify?

Welcome!

Nice CAD. Were these done with FreeCAD? Did you find it pretty straightforward? I have never used it before.

Mark was referring to the clearance masks that can be found on: Universal Derailleur Hanger

Maybe this thread should be re-named because a UDH dropout is actually being designed for Transmission specifications.

Your design more or less fits, except for a few MM on the bottom and a tiny bit of the flange at the top:

I think you might be confusing yourself with the DS and NDS symmetry, I have done the exact same thing before.

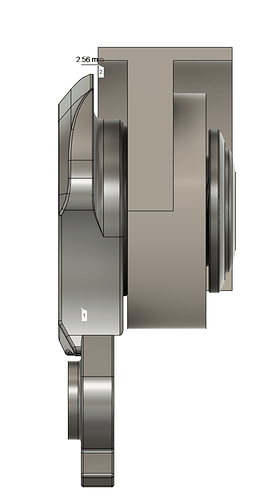

DS: The distance from the axle face (on the hanger) to the flange is 2.56mm outwards

NDS: The distance from the axle face (on the hanger) to the flange is 3.5mm inwards

This asymmetry/symmetry is actually the most difficult part of designing the UDH dropouts. The Paragon dropout (DR0072) accommodates the asymmetry by:

- having a wide flange

- “offsetting” NDS hood 2.5mm outwards to match the DS hood

I think this works pretty well for mountain bikes, but it runs into issues with gravel (flatmount gets in the way) and steel bikes (really bulky).

When I get some time I was going to try re-designing the NDS paragon dropout to be asymmetric. The asymmetric stays are annoying, but it will improve flatmounts and make the dropout smaller, so it may be the lesser of two evils.

Maybe you can explore that option? I recommend adding the the chainstays in, it can help you visualize the interface of the dropouts to the chainstays.

Actually I need the feedback from anyone who more experts than me in this for our very first own custom frames (and may outsource for the manufacture vendor), and I really lookin in to PMW round UDH as solid and proven references

Well understood and thanks, Mark!

Really happy to read your detailed feedback, Daniel! appreciate it.

FreeCAD is the only great and accessible CAD tools for now, few bug as expected on M1 Mac that annoy me few months but can’t really complain about it for pretty good community support ![]()

Also I did slight adjustment on the offset hood and flange on the round version, please check the step files here ![]()

ACD-04(UDH).step (1.5 MB)

Visual wise, from me, this one looks better refinement and convincing after print them out with Dark Black PowerResin, unfortunately hard to find UDH hanger/Eagle GX UDH nearby to fitting test in Indonesia even asking authorized SRAM distributor can’t estimate them clearly lol