It’s in 19.5 version. Should be released soon.

@mark_pmw Thank you Mark, that’s very kind. And yes, the new standard may not be ideal for steel bikes but I’m sure the options for dropouts and compatible components will only improve with time.

@terraformbicycles Congrats! You’ve found the first typo! That was an easter egg just to see if you were paying attention. ![]()

It was a typo so thank you for catching that. If you open up the document again, you’ll see it’s updated to Rev B and the dimensions have been adjusted to the 20mm nominal width that they have been machined to by Huston Precision.

For our own frames, we typically will start with 0.75" (19.05mm) tubing that is then ovalized to roughly 0.5" wide and given a single bend.

To help answer your question I modified the stays in my model to match a 0.75" round chainstay and this is what it looks like;

There is a little room to get a fillet in there but I would recommend ovalizing the tube just at the end to get you a bit more room for a fillet. With the large area of the Fastback Flange that you braze to, the small ovalization will blend well with the fillet.

I hadn’t planned to offer the spacers as it I had assumed that most people would be making their own on a lathe but I realize now that’s a poor assumption. I have the drawings made up and they will be produced and put up on the website but for now, I’ll machine them by hand upon request.

And thank you to @sikocycles about when the update will be rolling out.

Brent said early July he thinks it will be released

The ovalization part isn’t too bad. I was using Lichen dropouts for a while and the miter was not easy after ovalization, but they are round and yours are flat.

If I have time to make myself some new MTBs this winter I’ll try them out!

I need to take better pictures when I’m building the next frame, but those flats were designed to let you “belt sander” the chainstays into fit after you might the BB interface. Helps with the overall alignment and makes it a bit more tolerant to error (face to face contact at an angle means that any deviation is a fraction of a change in the length) and hopefully fewer scrapped chainstays. Not that I have any idea what that’s like at all. . . ![]()

Let me know if you have any more questions and I’ll be happy to help.

There’s a few 19mm tapered chainstays that can also solve this issue:

@WHilgenberg ![]() Setting a new standard for dropout product release and documentation!

Setting a new standard for dropout product release and documentation!

I can’t order from frame depot. I think you need to be a real company.

Those to look great.

@BikeFabSupply can get you anything you need from BFD.

That’s good to know. Thanks you for the info

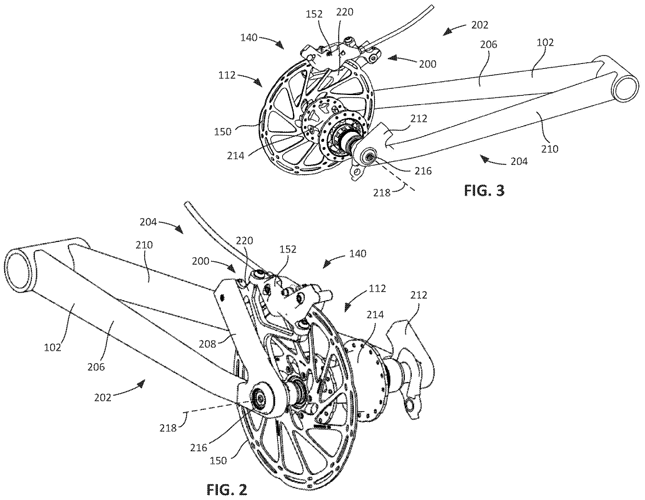

and just to add some more work to our design schedules. SRAM have filed a patent for a similar sort of thing on the NDS with a axle mounted brake mount. There are the usual pros and cons and like the UDH is a puzzle at first. From what I can tell the frames ends are mirrored ie. same dimension inerface as UDH and that it uses current caliper and hub inerface dimensions. So no changes to components.

I’ve commented elsewhere this will have been driven by the big box carbon frame brands and it makes sense to them. Whether you adopt it for your bikes is entirely up to you, as the current interface works and will still work…until they decide to change the caliper mount standards. Which I don’t see for a little while yet.

Thoughts?

Caliper mounts have changed a lot over the years: Hayes, ISO, post and flat mount. We have been able to adapt quickly to the evolution. With these choices available, it seems unlikely that we’ll see another type of mount anytime soon, but you never know!

Sram is hosting a marketing webinar tommorrow that appears to be MTB-themed. Perhaps they’ll announce this brake mount then.

I’d love to see a four pot flat mount caliper. That would at least cut the height of the adapters down. I’d be surprised if they changed calipers anytime soon. They are trying to reduce SKU numbers not increase them.

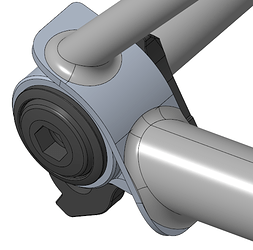

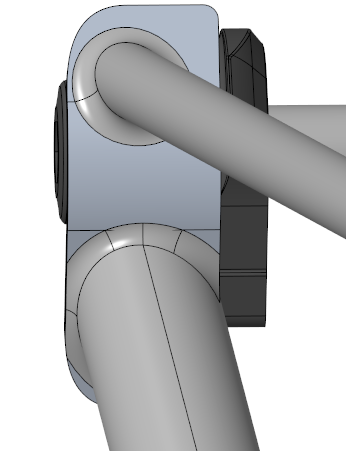

I started modelling the new Sram brake carrier from the patent documents. I’m convinced from that exercise this really only benefits companies building frames from carbon and those building in big numbers in metal. Saves a whole operation in getting brake mounts to spec in the factory as there is scope for the torque arm anchor to float on the pin before fixing in place. It also uses a 20mm hole so I believe frame ends can be just mirrored.

Interestingly, Shimano Australia are running a tech training day next week where we are going to find out about of bunch of 12 spd stuff that hasn’t been released yet. I’m hoping to get some intel on what Shimano are doing with their direct mount interface. I still believe they will base it on the 20x12 hole that Sram uses.

Sram announced GX level transmission group and some more lower tier stealth brakes. No word on the new brake mount and no 4-pot flat mount calipers.

Not sure if it’s what you’re looking for, but Hope has 4 piston calipers in a variety of flat mount configurations. You can spec them so you don’t need any adapters on the front or rear so they look super clean. I have them on my gravel bike and have been happy with them so far. Kind of pricey at retail but I think they work directly with a lot of builders.

https://www.hopetech.com/products/brakes/gravel-cx/rx4-caliper/

How did I completely miss that product. Cool. Thanks for the heads up.

The RX4+ is great, but the bleed process can be annoying FYI. I had to do a lot of babying each piston individually to get the air bubbles out.

In four months, we made inserts for our sliding dropouts, an insert for our rocker dropout, and now here is our take on the round dropout. Two versions, fixed and eccentric drive-sides:

https://www.instagram.com/p/Cu4jXStr5YB/?utm_source=ig_web_copy_link&igshid=MzRlODBiNWFlZA==

Coco are they on the website yet?