If you’d like the option of moving the cassette closer to the bb spindle. Is it plausible to make the chainring move left and right, to maintain a workable chain-straightness over a shorter distance?

A Rohloff system is 1600g. In comparison a Shimano XT 12sp cassette plus derailleur plus rear hub is about 500+300+300g (1100 total), or 500g lighter. So if you want a jackshaft design to save weight you have to get the extra hub, chain, and frame support members in under 500g.

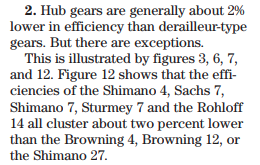

Rohloff Speedhubs used to seem extraordinarily expensive, but they are pretty reasonable compared to a lot of drivetrains today.

I use Shimano 12sp on my trail bikes but like using a Rohloff on my exploratory adventure bike. If I will be fording steams or may encounter snow I’d rather be on a Speedhub than derailleurs.

@Alex this was a great perspective, thanks!

I think there are still pretty big frictional losses and rotational weight location to contend with besides the weight, but 500 grams seems like a good target to shoot for.

I assume the addition of a single chain will not increase friction as much as an internal gear hub, but am really speaking with no direct measurements of anything yet.

Forgive me if I’m not seeing something, but I kind of see your design / project as a really complicated Supre Drive from Lal Bikes.

Maybe I’m missing something, but what I see is your design tries to achieve:

Making the derailleur hard to break / harder to hit.

Not introducing proprietary parts (like a supre drive derailleur)

but what it introduces is:

a very complicated frame

a higher COG

more weight

The constructive feedback here is good, but maybe what I’m wondering is:

If your system is trying to achieve what the supre-drive does, in what way does your design improve on it? Does it?

Props on running a good forum. We are VERY lucky to have you.

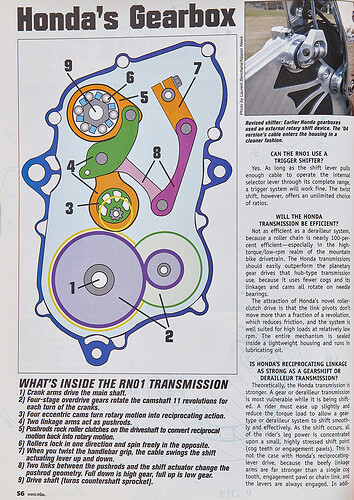

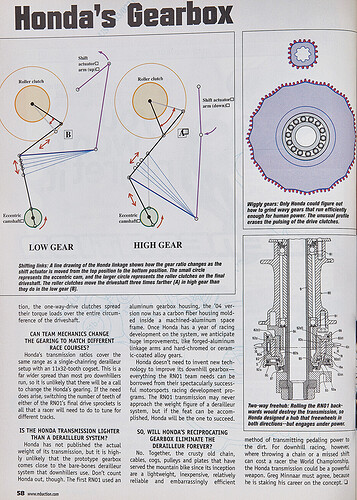

That’s, awesome. Never seen the inside of the Honda thing. Although I did imagine it being more spectacular. ![]()

Frictional losses from a Rohloff compared to a derailleur drivetrain are real but small. They are in the same ballpark as the losses from running with a dynohub and having your headlight turned on.

Human Power 52 or 54 had good measurements of all IGHs from then (it’s a 20+ year old article) and directly compared Shimano Ultegra 9sp with a Rohloff. The Rohloff design hasn’t changed since then.

I think jack-shafts have some interesting applications and they aren’t unusual in the recumbent world. They just seem unlikely to help with efficiency or weight. A commercial jackshaft design that I like is on davinci tandems. They’ve been using it for about 20 years.

I just wanted to add that I’m not against your project, creativity is good and it’s interesting to see fresh projects. Just questioning some of the facts used to make it. There is nothing wrong with making it “just because”.

Regarding efficiency of a 9sp system, it would be good to compare a Rolhoff to a modern 12 speed drivetrain. HP article below only has total system efficiency. Not sure how to convert watts lost to compare to the friction facts article below.

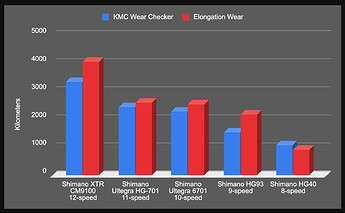

And friction facts shows that a 1x12 XTR chain lasts nearly double the distance to wear. It’s hard to compare the actual friction as there is no watt/watt comparison in the Friction facts article, but I’m assuming longevity = lower friction as the longevity is tied to wear, which is friction based?

My conclusion? You lose out on efficiency, and you lose out on shifting under load. And maybe or maybe not the internal system is heavier, but will have to build it to see what’s up.

@terraformbicycles appreciate the feedback!

I think this is broader than than just protecting the derailleur. Supre still requires use of a rear cassette. The issue is that cassettes require compromises for the design of rear wheels.

- Hub spacing can’t go much wider due to heel clearance of chainstays.

- Cassette cogs can’t be much larger due to derailleur cage length needed for chain growth (and therefore limitation is ground clearance of derailleur cage) .

- Rear hubs can’t get much lighter due to spoke length asymmetry needed for cassette spacing. Hub flanges on rear hub need to be taller allow better spoke bracing angle

- Cassette cog spacing can’t too much closer as chains can only be so narrow and adjustments to shifting get more finnicky as the margin of error is smaller.

- Low efficiency smallest cassette cog (10t) may therefore be a result of limitations on the largest cassette cog size + chainring clearance on frame.

So what happens if we take away all these limitations by shifting the cassette + derailleur to the front triangle? What are the potential benefits?

- smaller hub flanges, wider spoke bracing angle, reduce number of spokes, lighter hubs, lighter wheels?

- lower rear cassette cogs, larger ranges: 10-60t cassette? or an equivalent cassette size just shifted larger and therefore more efficient? 16-80t cassette - paired with a 24t front chainring?

- Potential for drivetrain to be shrouded and therefore more aerodynamic? Thinking more modern tri bike designs like Ceverlo P5x etc.

- Move cassette + drivetrain weight to center of bike, reduce rotating weight on wheel, better acceleration

IDK the end result here but there is potential that there are less limitations on gears in the front triangle.

This isn’t helping but:

I could imagine this design as a Singlespeed, and instead of the Cassette in the frame there would be an oversized and intricately designed bronze steampunk chainring ![]()

Hi all,

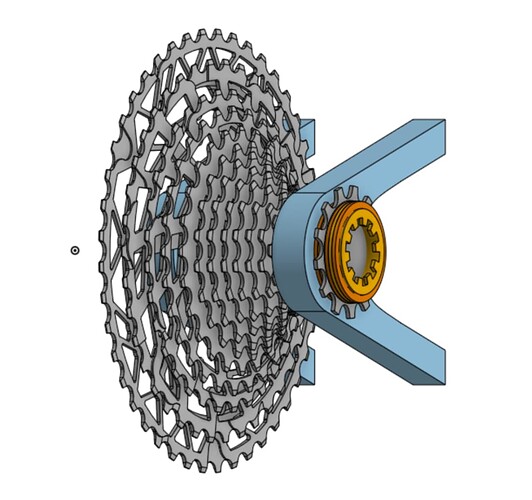

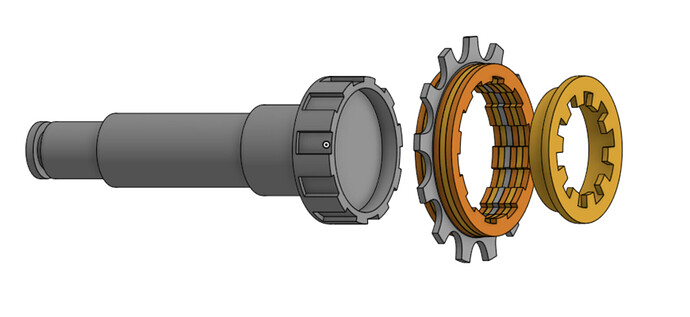

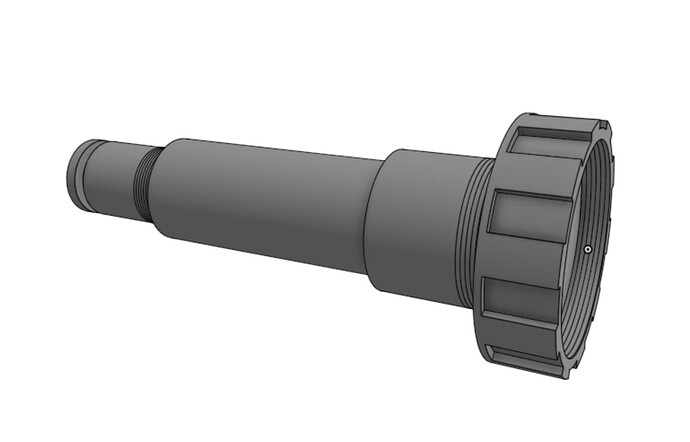

Still chipping away at this. Working on the mid-drive section and need some help. I am looking to create mounting adaptors for the various cassette standards, and am having trouble reading the SRAM XD engineering drawings as I don’t have much experience here, but I’m muddling through it.

What I’m looking for is the specifications for the rest of the cassette mounting interfaces:

- Shimano HG

- Shimano Microspline

- Campagnolo

Would also appreciate the CAD models if anyone has them. Obviously would shorten the production time.

Here’s some CAD screenshots of what I’m working on:

Appreciate any help.

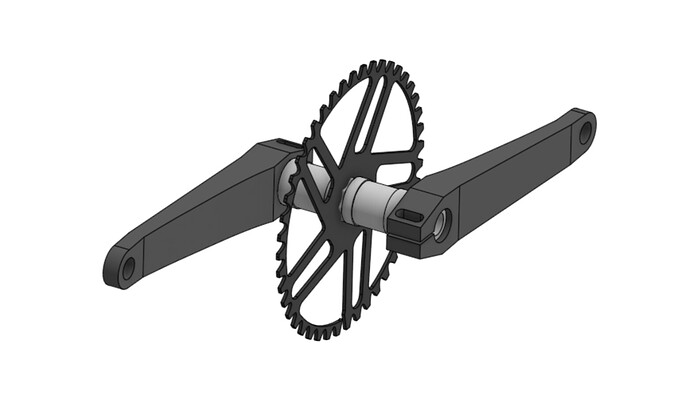

Here’s the most recent crankset if anyone is interested:

Our Counterpoint tandem has something similar, as the stoker (who is in front on this bike) has an freewheel and three cog freewheel that allows them to rest while the captain (in back on this bike) can keep pedaling.

This bike is such a fun tandem to take places, and it even works as sort of cargo bike!

Ah! I’d love to see some closer photos of the mechanism if you are able to ge them.

I’ll grab some this weekend