99% sure, it is just a leftover of a Columbus Cromor seat tube and Columbus Spirit headtube.

Here is another video that I gleaned some technique from. Though I don’t go for the full individual puddles stacked together, more like what Thom does, it gives an idea of proximity of torch , rod and metal. Get teh torch in there and don’t bescared to burn teh flux in teh enxt couple goes. Get the metal hot and experiment with when the flux starst to burn and when the filler sticks. Then back off everything a little and work you way back up to the sweet spot.

Nice job! I also have seen your vídeo before. I have been waiting for the gas bottles for over 2 months, so i have seen hundreds of vídeos, photos and read here and there…

Today I will try to get a better flame and do it closer and see what happens.

Thanks!

Well I am back, and the problem continues. (videos still uploading)

I tried again with tip nº 0, adjust the flame to neutral, or at least it looks to me. I heated a bit the bigger tube, when it turned hot as supposed, i tried to put the torch closer, waited to turn it a bit red there (it didn’t get red really), so again the bronze didn’t melt and start with the small balls.

Here is the vídeo. First 3 minutes I’m trying to set the flame, and at the end of the vídeo, the tip got dirty (because i was so close maybe?) so it started to whistle. I turned off everything, acetylene first in the torch, then oxygen, and the acetylene in the bottle and the oxygen, remove all the gas in the pipes, and close the regulators. It sounded like an internal flashback in the torch, as i have read and see in the theoretical situations that can happen. Nothing happend.

Here is the result:

And here it is when i remove the tip nº 0, i think it’s all dirty there because of the time i have been trying to set the flame or all the pops…

So i cleaned a bit the torch, just with a wet cloth and dried it, and put on the tip nº 1 i have.

I tried the same procedure, set the flame to neutral, heat the same piece (i add more flux), try to get closer when it looks hot, but again i don’t see it get red and i can’t get closer. Also i try many things, like don’t move it, put just the arrow of the internal cone, closer, more far… it doesn’t melt.

Again the tip got dirty in the hole, so i decided to stop.

Here is the video, again with the Fk* pop at the end.

I decided to give one more try, this time with the oxygen a bit lower, like 6-7 PSI. I cleaned the tip nº 1 and started again. But then it happens again, what it has happened before (not always) with the other tip.

When setting the flame, the internal cone starts to get bigger and smaller itself. This time i looked at the regulators, and the oxygen pressure indicator was going up and down a little bit, mostly you can’t see it, but it moves with the rhythm of the flame up and down, so i stopped everything.

I don’t know, everything is new, i built it myself (just secure the pipes and put the flashback arrestor no more than 1 meter from the torch as the manual said.

At this point im a bit frustrated, as my first frame is ready to weld for 3 months, waited a long time for all the brazing kit, and of course know I had to practice and my first fillet will be a bit disaster. But if i can’t even melt the bronze, so it means i am doing something wrong, or something is not working on my welding kit.

I will have to find someone who tests my installation or ask someone to show me in real how they do it to find the problem (i already asked, but there is no one around and it’s easy to meet).

Thanks for your help again. I will keep trying, but have to find the problem here first.

Sucks to see you having troubles and not being able to help much from afar!

Your tips will get dirty and occasionally partially clogged and need cleaning/ replacing.

It sounds like some trouble-shooting is needed to figure out what’s causing the fluctuating oxy pressure. Some components don’t work well at low pressures, regulators, flash back arrestors, check valves etc. Obviously be careful not to exceed safe pressures with your acetylene but maybe running the oxygen at a higher pressure at the regulator will give you a more stable pressure? (Sorry I know I suggested you do the opposite in my last post!). Or you could simply have a faulty regulator.

Hopefully if you get that sorted you will see better results.

I tried to find the manual of this torch/tip, no luck. Maybe i have just to set up a bit more than 10 the pressure of the oxygen. I will have to do more tests, but don’t know if i will have time before i leave tomorrow. Thanks!

As @TDB said, It’s really hard to see what is going on with a flame in a video.

With a properly functioning Oxy/Acetylene light welding and brazing torch, the amount of time you dwelt in one place with the nozzle closer to the work than previous videos, the flame should blow a hole in the tube several times over.

There is something going on with your flame. Invest in a tip cleaner set( little wires)

Your torch does not resemble anything I am familiar with so I can’t provide more feedback than that and I only read and speak English.

After you troubleshoot the pressure fluctuation, which sounds like a regulator problem or check valve arrestor problem, you need to find out the capacity of your largest nozzle. I am not particularly safety conscious so keep that in mind if you choose to follow any of my advice:

With a clean nozzle, light your acetylene and turn it up until there is a a gap between the flame and the and torch tip. Then turn it down just till the gap goes away and add oxygen until the feather of excess acetylene goes away and you have a neutral flame. This is not the maximum output, but it’s in the upper quarter of capacity

If the torch is functioning properly and you can’t use a flame 1cm away from a .9 tube to melt a hole in a tube in far less than 30 seconds, it is undersized.

You should post pictures of your bottles, lines, and regulators first though.

Not sure what torch you are using but a 0 or 1 tip is probably too small. Most people using a Victor J28 use at least a 3 or 4 tip. Measure the orfice size and then compare to a Victor J28 #3 tip size. You should be able to make a .035” chromoly tube cherry red in only a few seconds

The diameter of the largest tip cleaner that will fit into my worn #2 J28 nozzle is .048"/ 1.2mm

While we’re at it I use a #1 swaged brazing nozzle 95% of the time. These have a 0.9mm hole. For bronze and silver.

For some bronze stuff I break out the #2 which has a 1.2mm hole.

" # ACETYLENE HEAD N1 (0,5-1MM)"is the description of the largest torch head you bought. I wonder what this means, I’m assuming thickness of the work.

It appears to be a very light duty torch that’s primarily marketed to jewelers. I think you are going to need to find a bigger head.

I will give it a try again tomorrow morning to see if, with a bit more pressure of oxygen, the fluctuation disappears, and following these steps.

The thing is, when i try to get the neutral flame, even if i open de oxygen after open the acetylene at the minimun with a bit of smoke, even if i open completly the oxygen, i cant get the neutral flame, i have to close the acetylene even more to get the little cone, so maybe im not getting enough oxygen in the mix (or is the problem of the regulators and this fluctuation).

I will meassure the 2 tips i have for this torch, but i just bought everything in the national gas company, as they have a central in the city im am in Latvia, so i can have the bottles of gas there (dont have my little van here, just bicycle to move around).

The torch it is for welding, not jewelry, but i bought the smallest one as what we do (not me for the moment), needs something handly to move around the tubes. I can buy number 2 or 3, as they wanted me to sell this, but i said for fillet braze most people use number 0 or 1 for most of the work.

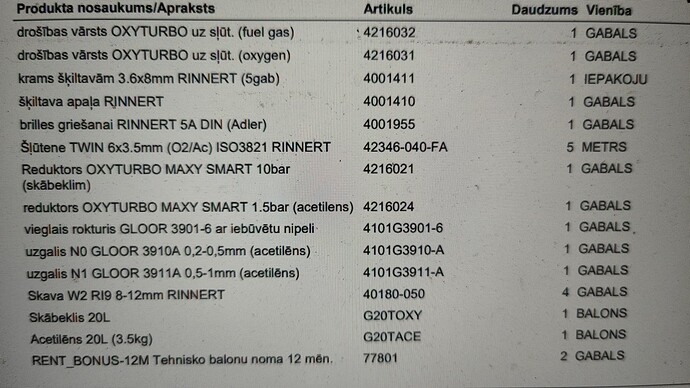

This is what i get and what i have, 21 litres bottles, and all the kit.

And yes, i try to do it all safe and following the safety rules

I apreciate your advices and time to solve this mistery of the sheep pellets.

Here i found some info about the torch. It is a Gloor brand and it is called in some places like gloor lilliput: Handgreep Gloor Lilliput

And this what i bought:

Tip Nº 0: 0,2-0,5mm

Tip Nº 1: 0,5-1mm

Your steel should be glowing red hot and you should melt the bronze by touching it to the steel rather than melting the bronze with the flame from the torch.

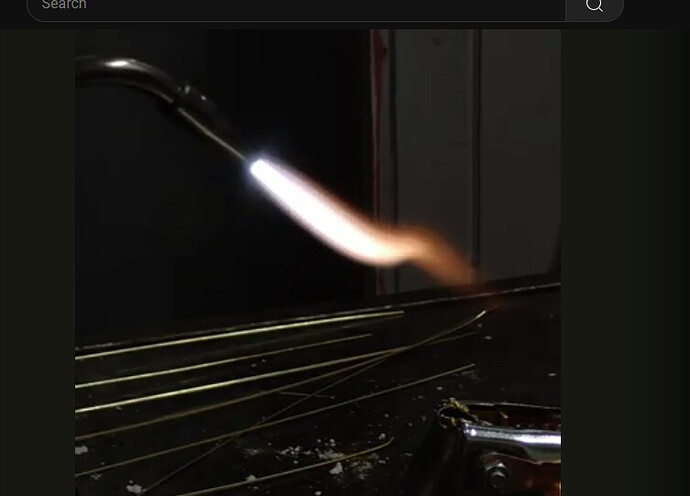

Something looks off with your torch flame. I grabbed this screenshot from your 5th test video – the tip of the flame looks too “feathery” to me – see how the orange tip curls? It should be much stronger and more well-defined than that with no orange, I think. Overall your flame is just not hot enough – in the amount of time that you’re holding the torch close to the parts in this video, the metal should be glowing bright red.

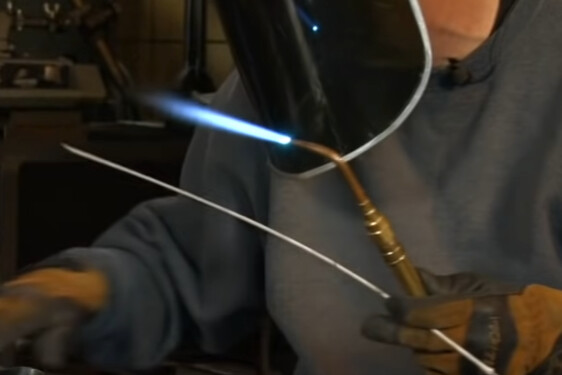

Compare that to the torch flame shown in this video – this flame is much bluer, there is no orange feather, and the inner cone is short, probably 10-15mm long. I wonder if you have a faulty regulator, or if your check valves or other accessories are too restrictive, causing too much of a pressure drop along your hoses?

This is the video we had to watch in my welding class, to learn about adjusting the OA torch flame. https://www.youtube.com/watch?v=kPW06n-27FY

great video. The flame also appeared crooked, as is mentioned in the video.

This video from This Old Tony is also great information – https://www.youtube.com/watch?v=-uPAjIOkLVA

Your torch tip holes are too small. You need something closer to .060” (1.5mm).

A word of caution, you are using a smaller bottle of acetylene. You must be careful not to use too big of a torch tip with that size bottle. Acetylene is no joke and you be aware of the dangers of having it around.

Put away the flux and the bronze. Once you are satisfied with your flame, hold the torch tip a few mm away from a ~.035” wall tube. It should be cherry red within 5 secs. Looking at your pics, you are barely melting the flux.

All of these examples look much too cold. You want to hold the cone on the metal while introducing the rod tip to that hot spot in the metal. In the first video, you moved the torch over and melted the rod. I don’t know that torch but I would guess it’s too small for brass or nickel silver.

Well, last update in a few days as I’m going out to Spain.

I tried again today with some little changes.

With the bigger tip i have at the moment, Nº 1 (0,5-1mm), that i cleaned a bit, i put the regulators with 4,5 PSI in the acetylene (0.5 less than other test), and tried with 12 PSI in oxygen and also with less, around 7 PSI. The result it is mostly the same:

- Difficult to get the neutral flame as i have to close the acetylene to the minimum after open the oxygen like to the maximum in the torch, so i try up and down, but at the end i dont get the heat, or still doing something wrong setting up the flame.

I didn’t see the oxygen fluctuation this time, so I’m not sure what is happening there when it appears.

- Envelope cone or flame was a bit orange, compared to the vídeos posted here yesterday.

Solutions i will take to solve this mystery:

-

I will ask if someone who uses gas welding here can come and check what is happening or what im doing wrong. I dont know if i can find someone.

-

I have asked some people who used to do fillet braze courses, and im waiting for an answer. They live in other countries, but everything to do it properly, safe and beautifull.

-

I will also buy the next 2 acetylene tips for this torch, nº 2 and nº 3, just to have then around and test if there is any difference.

-

In the last case, I will find a better torch, more commonly used. This cost me around 100e with the tips.

-

Someone said here my bottles are small for this use, but i think they are quite big with their 20 litres. My idea was to learn how to do a nice fillet before starting, then tag the frame i have here ready in my jig, and finish 2 more frames i have in mind and i already have all the parts to cut and miter. Then fillet braze everything. So im not going to braze again in some weeks, maybe months until i finish the other 2 or 3 new frames. I mean, im not going to be brazing all weeks.

So no brazing photos or vídeos today as they looks the same, metal didnt get red.

Anyone interested in what im trying to build you can see on my insta, but something close to this:

Any news i wil leave it here just incase someone has a similar problem and can get the solution in the forum.

Thanks to everyone!