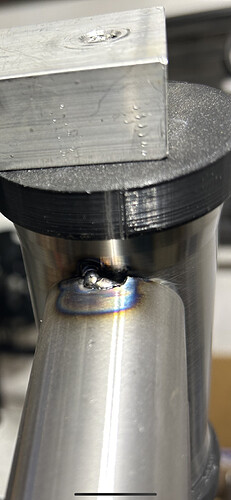

Did you run out of argon?

The tank is quite low, but it is welding fine on practice material so should be good. Never had empty tank, maybe it is the problem, just that damn corner makes it act up.

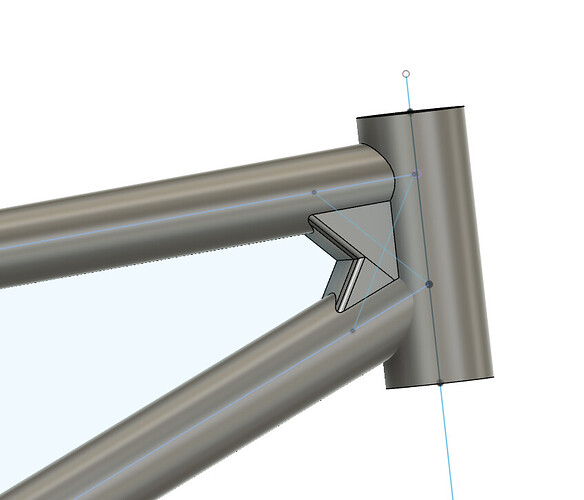

This looks like a gas issue, basically what’s happening as you cross the flat section and coming around to approach your turn back into your deep miter there, you are losing your gas coverage. The tubes act as somewhat of a buffer keeping your gas in the general spot it’s blowing out from the torch, but if you are in a spot with essential no “backing” the gas coverage will dissipate more quickly.

Common solution here is to use tinfoil and create a backing dam of sorts to keep your argon contained in that area. Cheap and easy.

Also check your tungsten stick out, cup size, gas flow. Generally from your photos it looks like you are running a bit hot.

Also, if not having a breather hole is really causing issue, drill a tiny spot hole on the tube and plug weld it later, grind flat.

These videos have some great visual here on what’s happening with gas flow both with Cfh and joint shape. 1:32 in the miller vid is basically what’s happening here in your photo.

If you are not already using a gas lense would highly recommend the upgrade. You can get little starter kits that have all the appropriate torch parts and they are not too expensive these days.

#8 cup is fine for most stuff but also if you run a larger cup you will have more gas coverage if you find it to be a consistent pain point.

This vid is about aluminum but again a good visual on cfh, cup size with effect to gas flow.

I’m using #8 cup with gas lens. I had quite a lot of stick out (more than usual). I will try the tinfoil trick.

Never had that problem before, and it is strange because I had just finished welding the other side without problems, maybe I had better welding angle or something. But I did clean it up 3 times and every time same problem/same spot so that parts is very much cooked now.

Very helpful thank you.

Ooof that’s rough.

A few thoughts:

-

If you’re re-welding that area you might need to go a bit deeper to remove the junk from the previous welding attempts. (e.g. cut off wheel)

-

Sometimes a smaller cup works better than a larger cup especially if you’re having a hard time laying down beads and holding the torch in that area.

-

If you use a foil dam try pulsing the torch quickly a few times (no welding) to fill up the area with argon. Remember that argon is heavier than air.

-

Hard to check now but is the inside of the square tube clean? If that area had some rust/contamination on the back side this could be an issue as well. (Unlikely but still a possibility).

Drilled a hole, cut it cleanish, wrapped tinfoil = success.

I will finish it when I have plenty of time to not rush it.

Also did not ruin my seat tube collar this time.

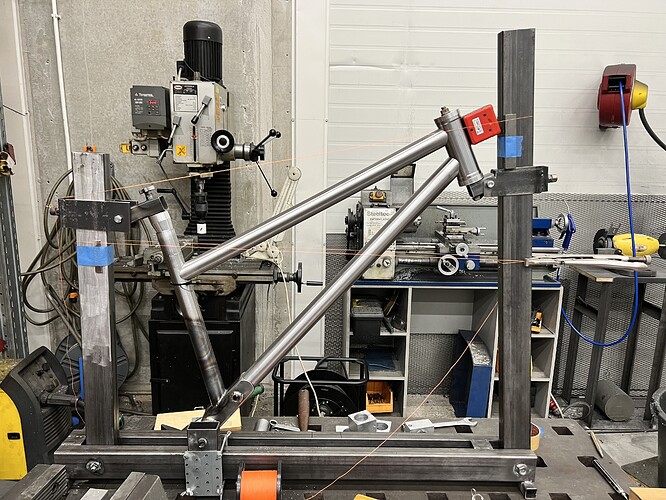

Front triangle is tacked. Made a little hole between seat collar and seat tube. Tacking sequence was wrong and tubes started to pull everywhere. Took a long time.

Aligned with laser, digital angle gauge and strings.

Edit: I really wish I had HF ignition and Flex head.

It’s a bike! Great progress!

Been welding. Managed to make an impressive hole. Big enought that I think filling it is not enough. It is bottom of TT. What to do with it?

Looks like it’s time for a new TT… if there was a little more HT overhang on the DT you could re-mitre both tubes and make the frame a few mm shorter but in this case I think this is not really possible

It doesn’t seem too crazy, usually I let everything cool really well, then re start on the un welded side of the hole, add a bit of extra filler when starting the weld, let it cool real well again and come back to close up the hole later. I’m not a professional and assume my method is kind of hack. I feel like this has happened to me on both head tubes of my most recent bikes. I always find the difference in thickness between the head tube and tt/dt challenging.

Edited to add a photo of the hole I blew in the top tube of my mtb while tacking

I think you should attempt to fill that hole before you consider replacing the tube or adding a gusset.

- Here’s the thing, you’re probably going to blow holes in shit a lot with your first 6-10 frames. Learning how to navigate around that (huge) frustration is a great skill for bikes . . . and for everything else you do with welding.

- The worst thing that will happen is you’ll totally mess up and have to remove the tt and then grind the HT.

Once the repair is done then worry about gussets. But in reality, if you’re getting into this bike building thing, you’ll probably want to build a V2 before the frame fails.

Fill the hole. Ride the bike. Make it again.

I agree with @SoyWater. Fill it. Ride it. Build a new one.

I have done the same and filled it. Part of learning is filling holes.

It is time to buy a rear shock. Im cheap so looking for an affordable options. Coil or Air? What would you guys prefer?

Rockshox deluxe ultimate air is very affordable.

Bomber coil is an option.

New rockshox ultimate coil with HBO if it gets restocked is the most expensive option.

Update soon. Got one gusset to weld, then the front part is finished.

I prefer coil, most I have used have been fine. Main thing is making sure it has a tune in the ballpark of what you need.

If there’s any tuners nearby you could see what they recommend, it might be a bit more than the RRP but you are more likely to get something that works well straight off the bat