Can you get some dirt and grime on your tools. I’m feeling a little inadequate over here. ![]()

Haha. I know, I know. I am very OCD when it comes to this one activity! Not to worry… the issues are all mine here, not yours : ).

-Chris

You are such a show off! It must be a wonderful place to spend a few hours working with metal.

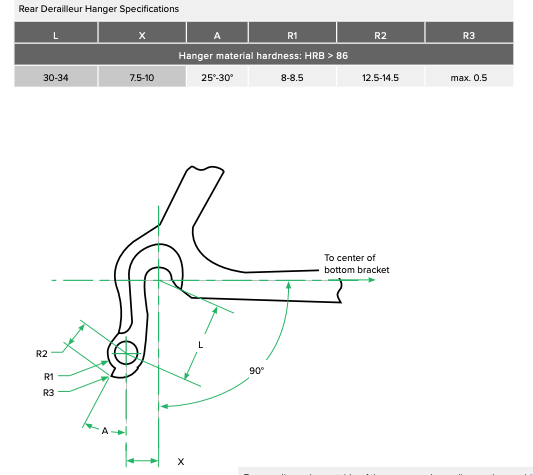

Super simple tool I made today. Sram frame fit says dimension X needs to be 7.5-10mm

So I made a wide washer with a radius of 8.75mm to go on the end of the dummy axle. Drop a string line down and rotate the dummy axle in the jig til the string is in the centre of the derailleur mounting hole

My jig is backwards so the view isn’t great but seems to do the trick!

Here are a couple of stock stands that are shop made, all from left over materials. I don’t remember where the railroad cart wheel came from, but it is one of my favorite uses for weird heavy things.

I put together this seat stay miter jig yesterday, wasn’t sure if it would be rigid enough but it worked fine. There’s some 3d printed vee blocks between the extrusion and the tubes.

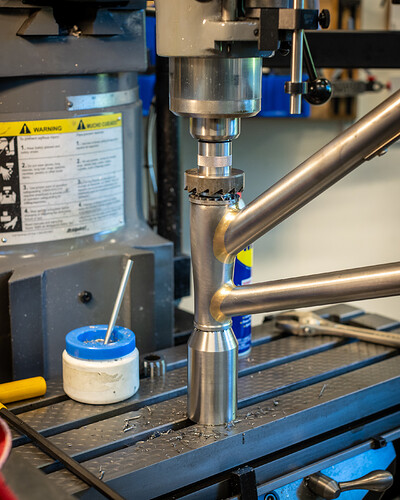

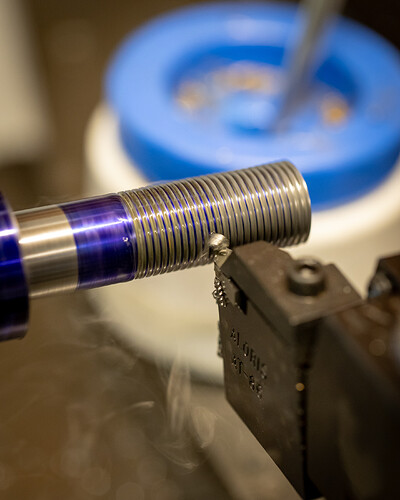

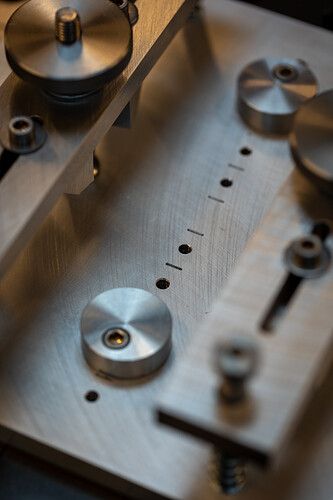

Made a head tube reaming/facing setup for the Bridgeport today. Mount the base, locate the center with the removable pin, and then go wild. Pretty good. I think Farr makes a similar tool.

That is beautiful. Well done

Farr used to make one. I asked him a while ago and he said he was not making them because he was too busy.

My extremely humble contribution to this thread: the simplest of buttcheckers. It was kind of a big deal on my IG back in 2020 - THREE comments.

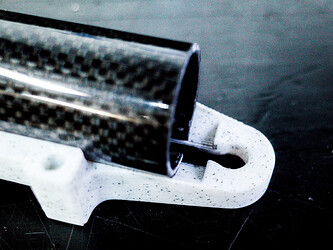

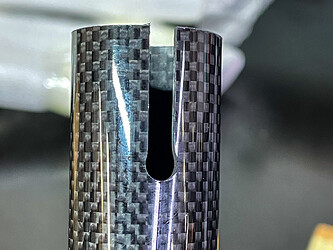

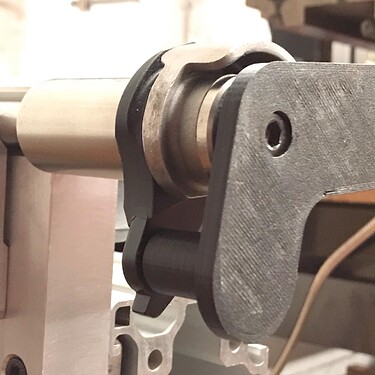

Had to come up with a way to cut seat tube slots in a carbon tube in a consistent manner without using a milling machine or other large tooling.

After some tinkering at the computer, and getting a 3D print done at a mates place, this is the result.

Turned my dremel and a carbide cutter into a kind of reverse routing device with the help of a tiny bearing. The 3D printed tube block features a shape that results in a 5mm wide slot, complete with a teardrop shape at the bottom. The built-in stop ensures that the slot is at exactly the same depth each time

Super quick to set up and cut the slot. Minimal cleanup required afterwards. The photo of the finished slot was taken right after the masking tape came off - only minimal deburring needed. Confirmed working on steel as well. Stoked with this.

I also have a matching fixture using 2 drill bushings to drill the holes for the bidon bosses.

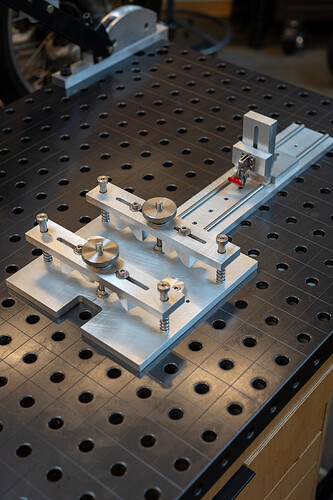

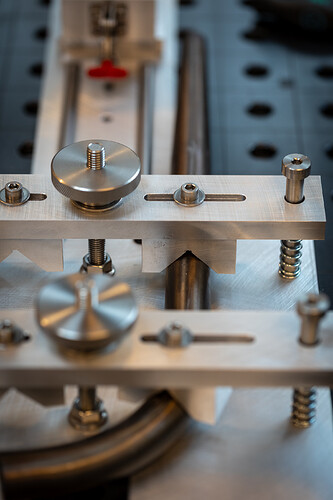

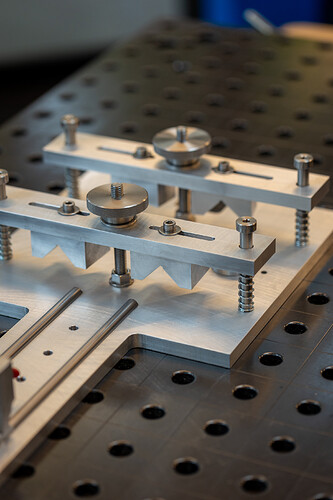

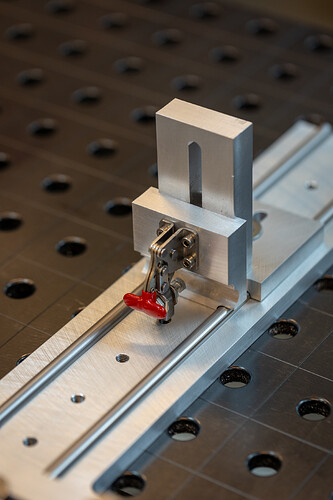

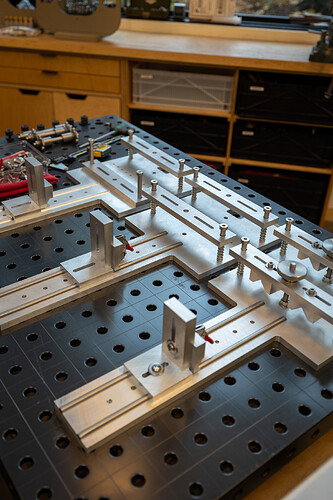

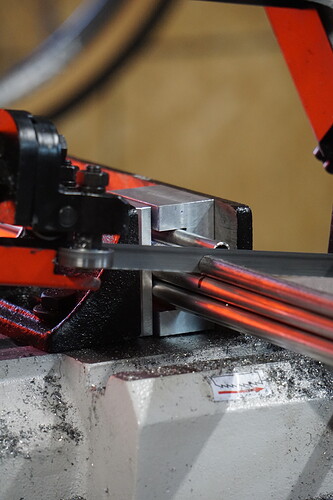

Made some unicrown fork mitering jigs for a couple of friends last week… Might keep one for myself. As usual, old Flickr feeds for inspiration. In this case, FortyFour and Meerglass.

Nice; I want to be your friend!

sweet! I am curious about the linear rails you are using. Is it a machined slot with a ball nose endmill + precision rod? How are the rods constrained? pressfit?

Any advantage of this method vs this vs T-slot extrusion?

Yah, they’re just tight tolerance drill rod. And yes, I machined the slot with a ball nose end mill in the matching diameter. They’re a snug fit, but I did secure them from underneath with screws as well.

Advantages seem to be… meh?… but I’ve been trying different things and wanted to give long rails like this a try. I can see myself doing it again in spots where I don’t want a bulky extrusion.

I made a tool to clock my UDH dropouts at the spec’d angle in my frame jig. 3D-printed ends fitted to a standard mitre track. It should work with any round BB post.

Printable files are on my Thingiverse: [UDH Clocking Tool by stuartm - Thingiverse]

Brilliant!

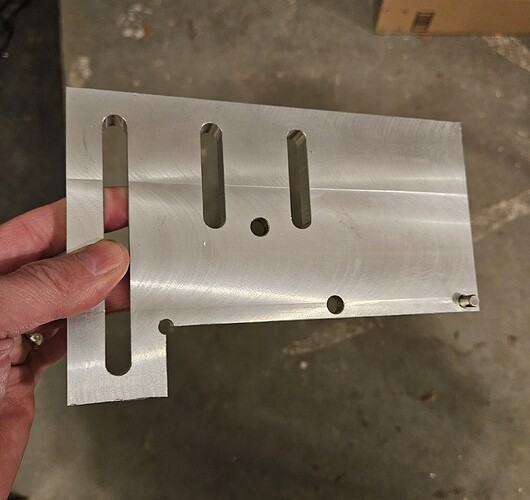

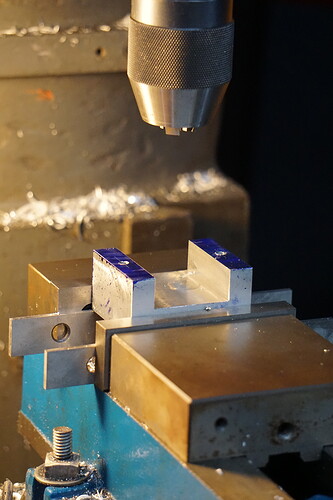

I have just been clamping on tube blocks to miter tubes in the mill. I wanted a way to test fit and then put the tube back in the mill without having to reset the angle and position so I made this plate. After the initial position is set I move the tube rest up to the tube and lock it down. I press the tube block up to the dowel pin and that holds the inside corner plate up to the edge of the vice. The slots seem to be working well with a carriage bolt.

This was a scrap plate and the 2 extra holes were already there…

Clever solution that will speed up mitering a lot I guess. ![]()

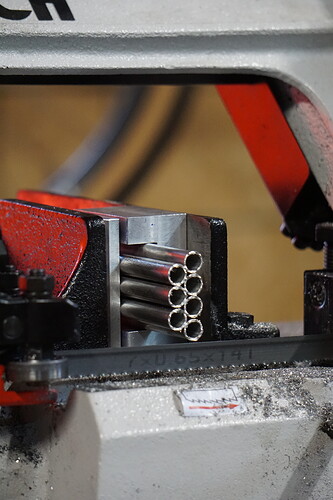

Not necessarily a frame building tool, but very useful for making lots of racks.

This holds 7 3/8" tubes that I use to make T-bars. The width of the channel is slightly wider than the combined width of 4 tubes, so that when the 3 tubes on the second layer are added, they push the first layer around and self align.