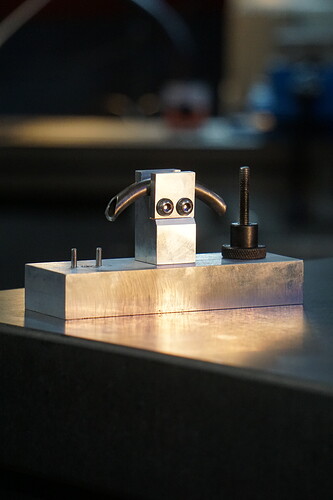

I’ve been working on a brake boss fixture – here’s V1 helping me put some center pull bosses on a friend’s bike… it was quite a good test to see what I want to change for next time, but it also worked well enough. V2 will have a wider axle clamp to self-center reduced-center axles, move the engraved scale closer to the center to make it easier to visually align the clamp, self-centering upper axle with a scale for widths added there as well. The Anvil version of this tool was an inspiration of course.

Here’s some tools I made to help make T-Bar racks. Theyre pretty crude, but are extremely useful.

The Bender is a ridgid 406 hand bender, I removed the fixed handle and attached the rest to a machined block attached to an aluminum plate. The plate has holes and stops to position the tubing and keep all the bends in phase.

A little video of the bender in use:

https://www.instagram.com/p/C0g1Tp6u41G/

Oh that’s who you are, I think I favorited one of your pictures on instagram about this fixture as I am making a similar one for chainstays!! Great work

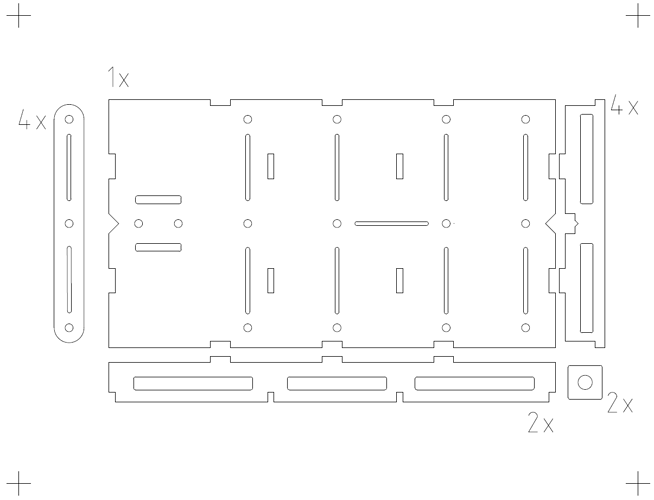

I am about to send mine to be lasercut:

Just finished making a jig for my swingarm assemblies. Its a little ghetto using material I have on hand. Its a prototype and hopefully will find time to build a nice one to replace it. I said that about my frame jig too!![]()

I made myself an electric dynafile of sorts by combining a contact arm and a $36 wen band file. If you leave the plastic silver guard off, you can fit the non-woven abrasive belts. This is not the most ergonomic belt sander out there but for under $100 it should work well for many tasks for a long while.

what band length are you using? 13"

18”. it came with a 1/2” belt but I’m going to 1/4”. I made the arm the same overall length as stock so it’s got good tension on it.

Wow! How did you make that wood tapered head tube? On a wood lathe? The wood tapered head tube looks fairly accurate. How did you get it so close in specs to the actual steel head tube?

I put it in my metal lathe and used the insert cutters on it as if it was aluminium. Did all the measured cuts and hole in one mount in the chuck. Then machined the arbor for a light press fit. I kind of arsed it getting no run out on the mill. That was a nice surprise.

A tool I made quite a few years ago when I was replacing a top tube and wanted to accurately measure the length. I now use it to set my mitre templates to the tubes sitting in the jig.

So often, the simplest tools are the best. That is brilliant.

This is genious, I must make one too! What is the base material you used for that, an old window blind?

Its a bit heavier than blind blades, its just aluminium extrusion from the local hardware. Flat would work too.

These are my brake mount fixtures. I did not want to modify my iso tab fixture to fit 1" dummy axles so I made a new one (top). The bottom one is fatmount 160.

Here is @Alex 's first frame fixture…which is now in my grateful hands…

(Ignore the dummy axle, I made that)

-Jim G