I’ve been starting to use the lathe for doing mitres on the truss style rocker I’ve been building. Need to make some dedicated tooling to do all the tubes on the lathe I think.

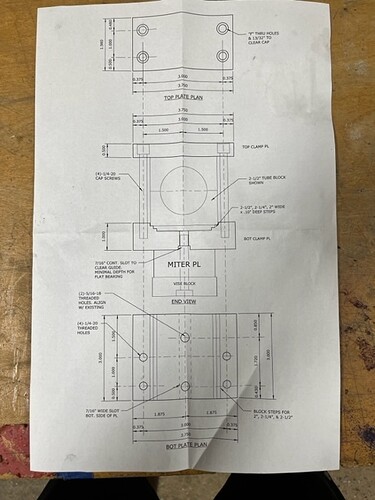

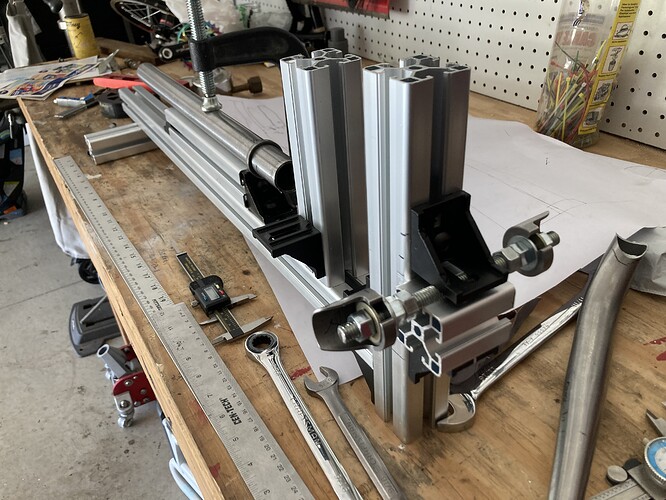

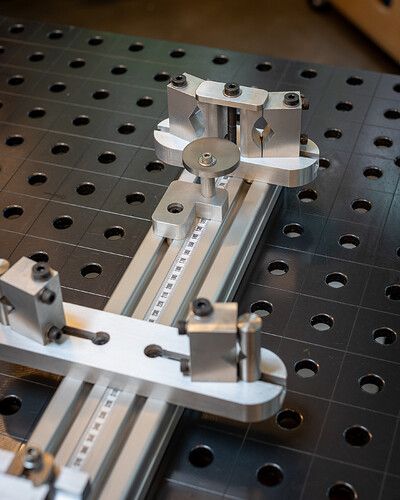

I’ve been working on a tube block vice jig for use with mitering tubes. It incorporates the Cobra Round Vise Grabber to make it easier to set angles.

The “Miter” Plate on top of the vice gripper has to be minimum 1" thick to be able to adjust the angle and clear the Kurt vice jaws edge.

Great idea! We usually use tube blocks to keep the tube in phase, but might as well use it to fixture it too! Two birds, one stone.

The steps are a great idea too, I am guessing they interface with the Paragon block sizes?

Yep, the steps in the base plate are for centering 2", 2-1/4", & 2-1/2" square tube blocks. 3" wide tube blocks would require another bottom and top plate so it can fit between the clamping screws.

That’s pretty brilliant! For round tubes, I just clamp the tube block directly, but your method allows for repeatable angled cuts which is great.

Thanks! You can also keep your location consistent on the milling machine by aligning the front of the tube block with the edge of the bottom plate. In case you are a little short on your miter, etc.

I don’t know if this really belongs here but I’m a believer in making things work.

It only had to work twice.

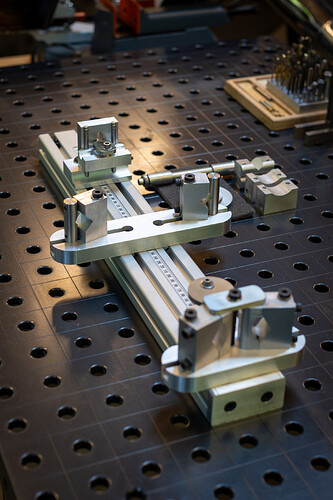

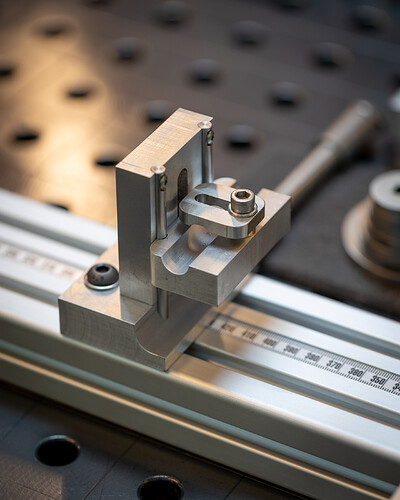

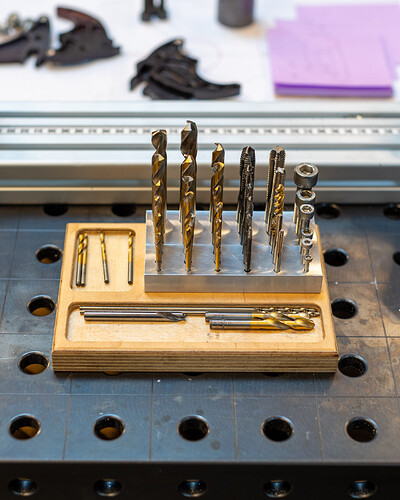

Great tool! I like those steps to hold the various tool block sizes. This is my hunk of scrap main miter tool, similar idea. Saves so much time setting the angle once and using the dro to tune in the length

Nice, simple yet gets the job done. Does the head of your mill pivot to set the angle of the cut?

Unfortunately I don’t have a DRO on the milling machine I have access to. So I will be using the old fashioned method and keeping it in position and adjust incrementally if necessary.

Looks like you’re using a bench-top mill, is that true? If so, is it worthy for mitering and basic frame parts?

I can’t get a full size mill in my space, but have been warned off the bench-top type because they aren’t stiff enough.

@Modulus-Dave I set the angle of the fixture in the vise with an angle finder.

@gschwell I’ve been using it for all of my bikes and have zero complaints. Sure it doesn’t have the torque or stiffness of a Bridgeport but it’s plenty enough to make accurate miters. Mine is a Weiss VM25L for reference

Now I see the plate in the vise in the background. Thanks.

At some point I may lose access to the milling machine I’ve been using so thanks for the info on your milling machine.

Thanks for the info!

I set out to build a budget fork fixture. For $70 and zero machining this thing nailed it.

I plan on adding some sticky rulers and printing a pointer to help line up the crown race as well as some better clamps for the steerer.

@Brad Whew did you get the black brackets? I’ve been really tempted to make a fork jig since my last hacked together jig used a 1" steerer Fork alignment gauge, and I’d like to have the option for 1 1/8" steerers. lol

I used these but I believe there are more accurate options from McCarr.

Iverntech 10pcs 35x39mm Corner Bracket for 4040 Aluminum Extrusion Profile 2 Hole Inside Brackets Connector with 20Pcs M8 Screws + 20Pcs M8 T Nuts https://a.co/d/1wE379k

This wins!

Started making a rack holding at the right angle device.

I used two 0 /90 degrees stems.

One stem goes on the fork steerer.

On that stem I brazed a piece of square tube so there is flat surface for an angle protractor.

The two stems are connected thru the bar clamp part.

The second stem has a piece of flat wher the other part of the protractor lands.

I’m sure everybody is lost on what I’m talking about.

Here’s some pictures

Just a quick’n’dirty positioning fixture for some suspension pickup points on a one-off squishy frame ![]()