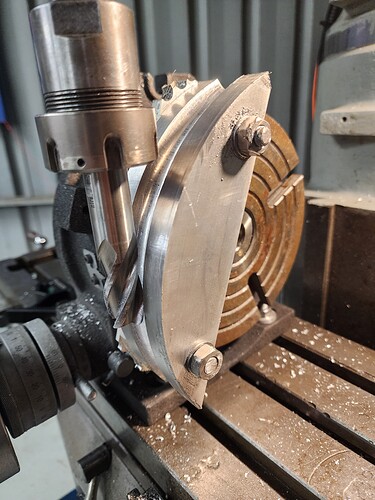

Tube bender for a 22 2mm chainstay.

I love this! Nice work.

Does the 3d printed material machine ok?

I don’t know. Haven’t tried machining it. It felt a bit sticky tapping the hole for the retainer.

3D printed Mill Tramming gauge. 3/8" center rod goes in a collet and each dial indicator is zeroed on a common surface to eliminate error from manufacturing.

Could the extrusion that mates with the BB face be rotated ~90° and attached directly to the piece with the drill bushings? Eliminates two parts, seems like same functionally.

I do realize eliminating parts isn’t that huge a benefit, especially after the dang thing is already made and working groovy! Just spitballin’

Not sure if I understand correctly what you mean… But I guess it would eliminate the lower, long extrusion.

I use the slot in the extrusion for centering the tube and to mildly clamp it down with the part that has the drill bushings in it.

But yeah, it mainly looks like that because I had exactly these lengths of extrusion in a box somewhere ![]()

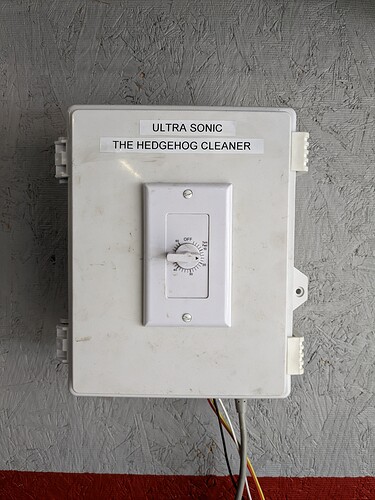

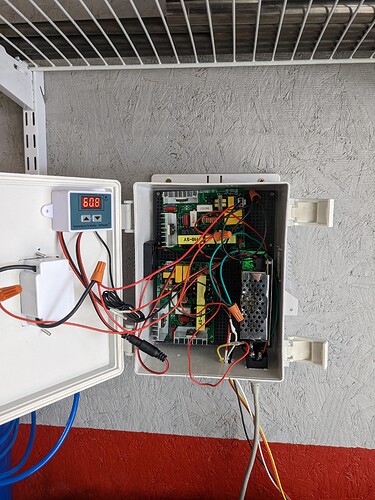

DIY ultrasonic cleaner. This was a fun project as I haven’t gotten to toy with electronics in a long time.

I plan to add a water heater element and an Arduino to control temp.

Hello, I’m interested with suche a tool,

Do you use it to clean flux after brazing ?

kind regards

It cleans off the flux. However, we have found that it’s good for cleaning off the oil inside the tubes. You can get it pretty close to bare metal.

What solution are you using?

White vinegar is pretty good at removing mill scale.

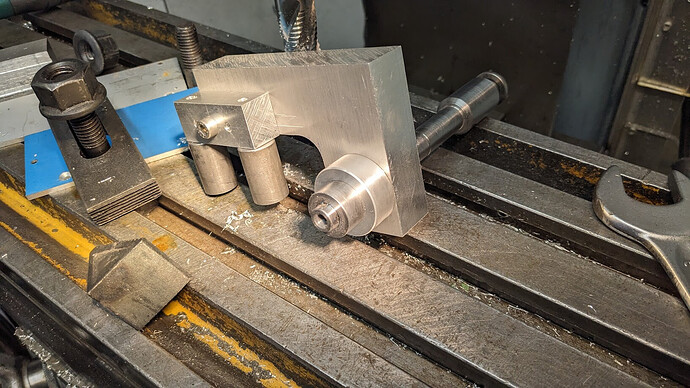

After staring at the parts sitting there for several months I finally started on my cordless bandfile. I still have a bunch of final tweaks to make, but it works which is a win for about an hour of work.

Thanks for posting your 3D printed tramming tool. It got me to finally make one and dial in the nod on my CNC machine. If you look closely you can see where I crashed a tool holder into it (my drill bit had too little stickout).

Excuse my potentially stupid question, but how do these things actually work? How do you zero the dials and how do you make sure the middle shaft is perpendicular to the reference plane of the dial gauges?

You set a reference point on the table, I used a small rare earth magnet set on one of the vise bolts. Zero out both indicators on that point. Move the head around so that you try both indicators from multiple angles and make sure that they still read zero on that point.

I originally used mismatched indicators and that worked fine too, but I got this matched pair of really small (and decent quality) ones and they worked perfectly for this. They were $35 for both on eBay, cheaper than new import ones would have cost.