This may be a bit of a contradiction: If you want to run Transmission down the road, that means you’re running something else in the meantime. Doesn’t that mean UDH? We do have to care about UDH if we want riders to have options.

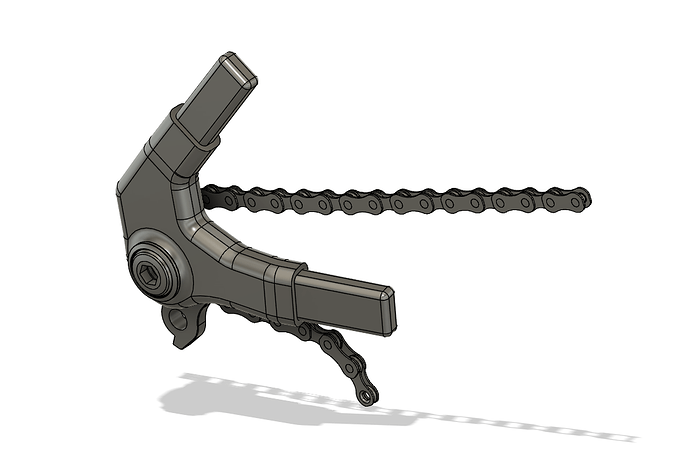

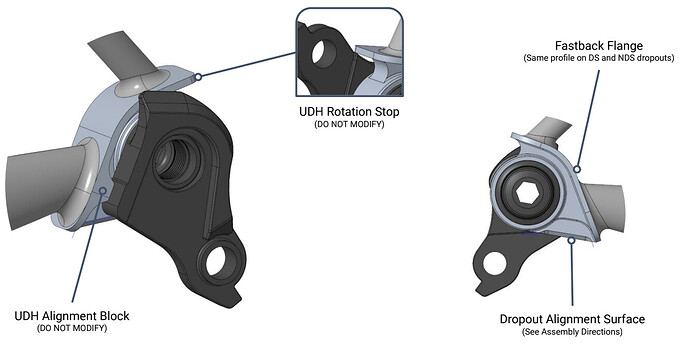

Our take on it is that anything we release has to be 100% compatible with SRAM’s specs. That way, when SRAM releases something else down the road, we can be sure it will work.

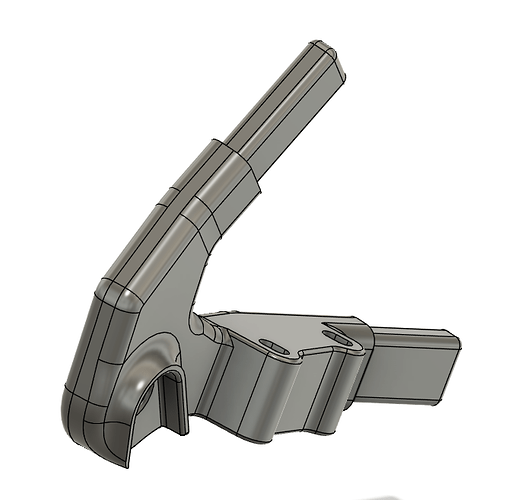

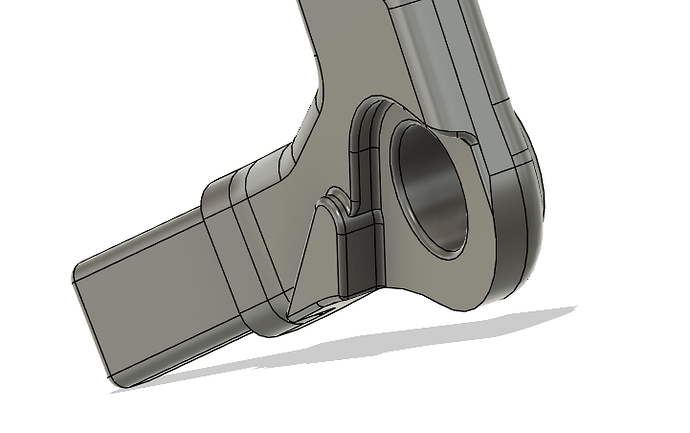

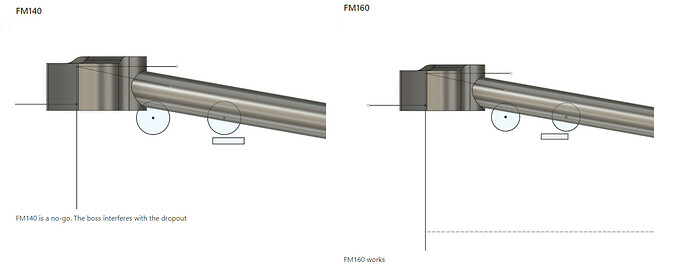

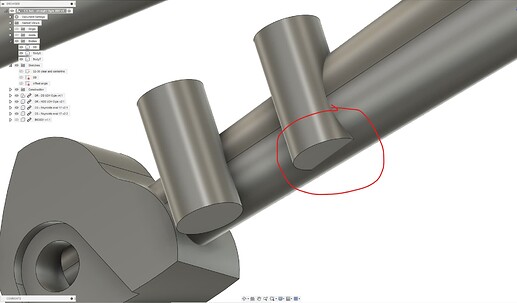

A lot of individual builders are making their own dropouts, that work for their style or method of building. Some are within SRAM’s specs, others may not be. It’s not enough to assemble the components and say it’s SRAM compatible. There are very specific clearances required; the best way to check these clearances is with CAD software. The latest specifications can be found at https://www.universalderailleurhanger.com/, scroll down to Downloads, there is a drawing and CAD package. Current revision is H.

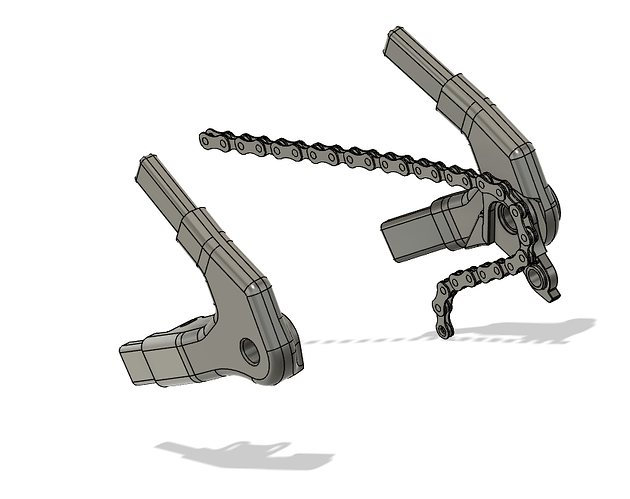

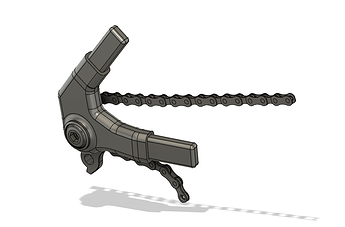

Our challenge now is making a fully compatible dropout in titanium that will accept 7/8" chainstays and 3/4" seatstays, is relatively light at a reasonable cost, and completely symmetric. We have a design finished, and we have confirmed with 3D prints. We will start machining next week, so builders will have them for bikes going to the MADE show.

Checking weights in our CAD software, the design is less than DR0065, our popular 12 mm round dropout.

Once titanium is done, we’ll do a similar design in steel. This will be easier, because steel stays are smaller that titanium.

Please watch CFF, our Instagram and our website for updates and availability.