Hey Kirk, take a look at https://www.intra-drive.com/ We are very close to launch with a Gearbox/Motor drive unit. We’ve been testing them in Scottish conditions (think very wet and very muddy) for a long time. We’re about to shift out of prototype stage and will be doing our first run of units in October. Volume production will follow early next year. We’re keeping as much of the manufacturing process in-house (including motor windings etc). We’re working to a very strong environmental model where sustainability, repair and rebuildability (is that a word?) are right at the front of our thinking. Check it out and let me know what you think.

Good to hear the progress with Intra drive! We are looking for ebike options for our Vittorio Globetrotter travelbike, and since Pinion has decided small companies are not worthy we are very interested in the Intra Drive unit. Also because it fits the Shimano mount and keeps options open for clients that prefer a “normal” drivetrain. Is there more info on the October run?

Steven,

I’ll keep an eye on your progress!

In the meantime you might enjoy this CVT Gearbox

it’s a CVT I developed for e-Bikes, based on the Pinion gearbox mount.

Cheers,

KP

Hi, your best bet is to drop an email to Cirdan Heughan (cirdan@intra-drive.com) he’s managing the pre-production / evaluation units. Tell him I sent you.

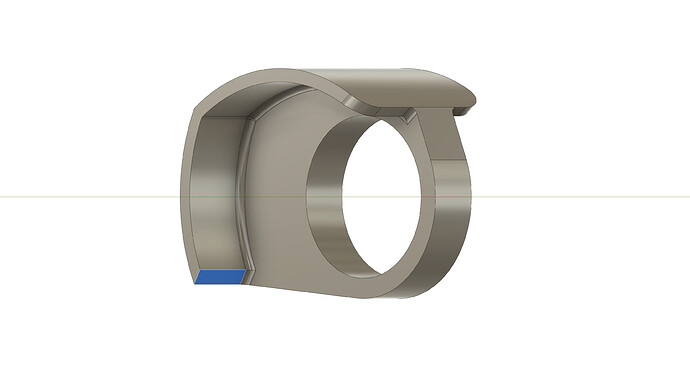

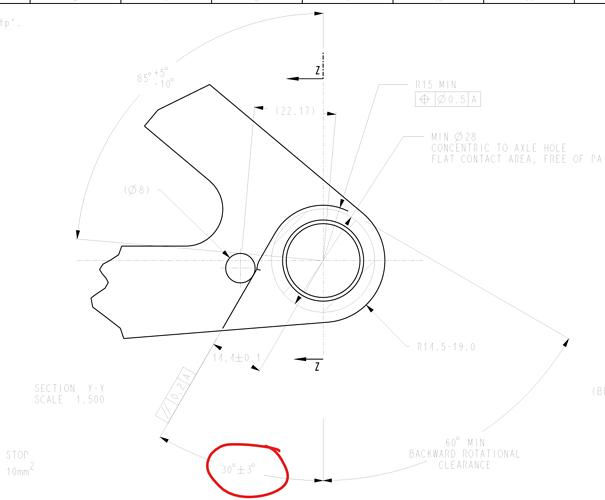

Bit late to the party. I designed some dropouts along the lines of my syntace style ones. Have been using the excellent Paragon ones so far but think that something a bit more personal may not be a bad idea. If ok I would still like to use the concentric-eccentric rings for a while (I found that to be very helpful with the x12 dropouts). Basically I recreated the discussion here with a number of iterations before I found this thread, and then decided to go down the “remove the fin” route. The result is ok, I think, if a bit on the chunky side still. Which leads to my question: I do not have a derailleur here at the moment to check, so does anyone have an idea how much forward rotation is possible/required with the Transmission type rear mechs before the mech touches the chain stay. Is there any information on that out there, by Sram themselves even? Thank you for any input.

That’s looking good!

By forward rotation, do you mean clockwise or counter-clockwise?

The UDH spec document tells you how much the derailleur is supposed to be able to rotate, and the 3D file with the clearance surfaces pretty much dictate how you can configure the hoods on the dropout.

I’ve got a 3D model of a T-type derailleur here and it can rotate a fair bit before interfering with the stays. The derailleur full mount will hit the hoods before anything touches either the seatstay or chainstay.

Thank you.

I am talking about counterclockwise. This dropout here meets the specs for the UDH given in the Sram manual. From the bikes I built with the Paragon DO I would say that before the 30° offset by 14.4mm that’s specified to position the UDH derailleur mounting hole in the right position for traditional mechs limits the rotation of the T-Tpye mech it has hit the chainstay already. Or am I wrong there?

I think you have answered it already. I am wrong obviously and the rotation with the t type mech is limited by the UDH stop before it hits the stay. Thank you.

Looks good! Very compact and unique design.

I would be careful. The fin serves as a placeholder for the 10t cog, since they moved it 2-3mm outboard. Make sure you check the clearance masks SRAM provides.

In real-world use, I can’t imagine the derailleur ever rotating that far back. The chain holds the derailleur in place. Rock strikes are also fractions of a second; the bike and derailleur will move out of the way, not continue to rotate backward.

In my opinion, the derailleur rotation stop was a decision made in their CAD, not tested in the real world. SRAM needed to specify something; otherwise, they would become responsible for broken frames and derailleurs.

thank you

I am talking about rotation in the other direction, counterclockwise when you look at it from the side. I thought it would be possible to do something a bit more compact if not the full potential 30° rotation where needed. The rotation stop at 30° is marked blue in the drawing here, and if

that were not needed there, live would be a bit easier.

From what I understand the fin is mainly there to protect e-bike stays. If the chain falls of the 10t cog and the motor would keep pulling the chain could damage the stays, hence they added the deflecting fin. At least this is the story I was told by a guy who used to be with Sram and knew the guy who did the UDH stuff. Semireliable, I guess. Still the UDH minus the fin sits flush with the hood, so the specs there are the same as they are with the fin, and clearance should not be an issue. Will check prior to pulling the trigger on the first batch obviously.

That was the story at release. The fin was to block out the space for the chain:

Make sure you check the mask.

If you take out that stop, the UDH hanger will no longer work. But if the dropout is for Transmision, then you don’t need that forward stop.

All good. I just got confused by the question how far it can rotate before hitting the seat stay. Hence me asking about the rotation direction.

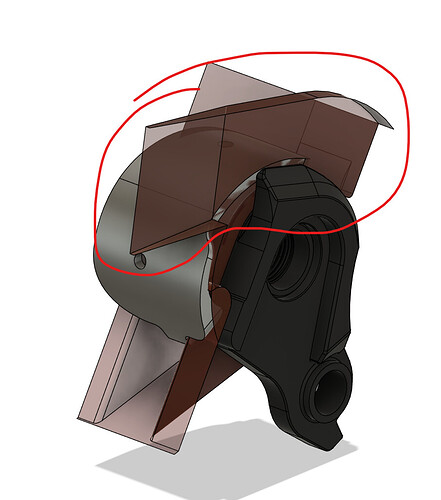

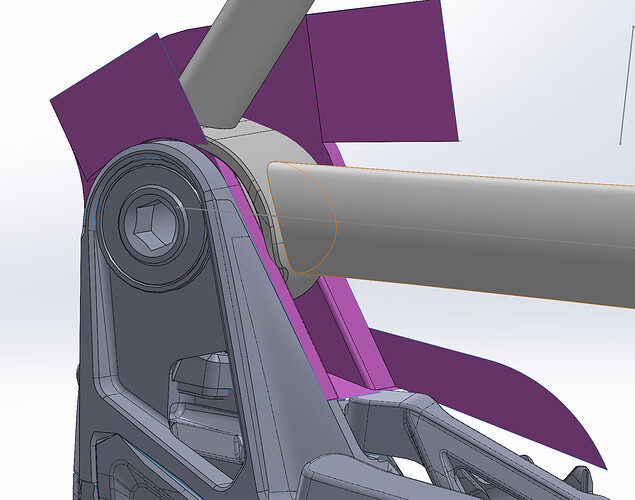

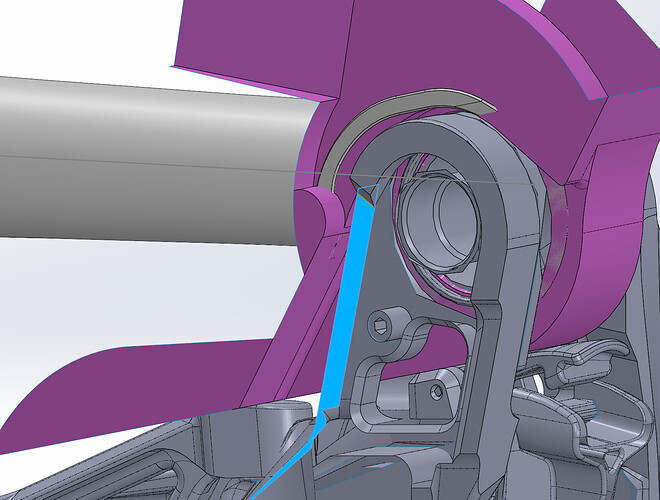

Here are screenshots with the clearance envelope showing (pink) and a mockup 3D XO Transmission derailleur from SRAM.

The front edge of the outside part of the full mount is aligned with the clearance surface.

This is what the inside looks like. The derailleur will not hit the rotation stop. So that stop, as @Daniel_Y already mentioned, is only for the UDH hanger and not the transmission derailleur.

We’ve had an Orbea Oiz with UDH in the workshop where they left out the stop stub. Guy had a pretty worn drivetrain and managed to have his XTR derailleur rotate all the way back and up, smashing and breaking the carbon seatstay. (and destroying the derailleur, cassette, chain and freehub. With great power/wattage comes great care of your material) So the stop definitely serves a purpose!

The idea is not to leave the stop out but to rotate it back a little, which means the dropout could be more compact. My feeling is that with T-Type mech this would probably work just fine, with UDH maybe not so much so.

You can rotate it back by 3 degrees and still be within UDH spec.

The problem with rotating it back more is that if you ever want to use the hanger, the derailleur attachment tang will be indexed incorrectly.

But as you say, no bigge if all you ever want to use is a T-type mech. It also wouldn’t be extremely difficult to just do a quick mode to the hanger if you find yourself needing to use one.

I have modified the drawing with the 3° tolerance, and it’s not a huge difference really. So maybe not worth the hassle. I was thinking about doing two versions, one for T-Type only, and the other one for UDH and T Type. Since I am a one man show with a consequently small output offering a ton of options with no discernible benefit may be a luxury I should try to do without.

@JMY if you’re looking for a side project, I would love for someone to make UDH to Transmission locating stops to ensure transmission derailleurs are properly clocked within the dropout. Similar to Newmen’s Torque Caps Adapters. Something to fill the gap between the UDH forward stop and the transmission derailleur.

I’ve seen too many Transmission Derailleurs mounted improperly because the chain length isn’t listed in sram’s app. Open really butchered it on their new launch bike.

But you can also just calculate the chainlength in the app if your bike is not listed. At least that’s how I did it for my very much unlisted bikes…

I have checked with printed samples now. Does not seem to be a problem with my design. Strictly speaking I am not sure it is a problem in general. I mean a 10-52 Eagle Cassette can be used either with a Transmission derailleur or with one on a UDH. The hub and the cassette remain the same, hence the horizontal positioning of the contact surface of the side of the hub against either the UDH in the slot or against the T-Type mech remain the same. If the space of the fin were indeed needed for shifting/the chain it would thus cause issues with the same wheel/cassette with a Sram UDH fitted derailleur because it would occupy a space needed for the chain. Does that make sense, or am I confused?

This is a misunderstanding. Eagle and Eagle Transmission cassettes are different and they are not cross-compatible with a regular Eagle vs. Transmission derailleur.

The Transmission cassette sits further outboard compared to a ‘regular’ Eagle cassesste, hence the fin and the difference in width.

Here’s a link to the SRAM compatibility database for Eagle AXS Transmission (T-Type)