Shit. Thanks for pointing this out.

Wouldn’t this be redundant if you make sure to use the right setup cog and chain length as per the AXS app, or the chart found HERE if the app doesn’t have all the options?

No problem!

just make one for my own road bike, utilize M5 and 1 nut as a back forth stopper. Not yet trying with transmissiln derailleur, but it works flawlessly with this setup

SRAM specifies a thru axle with a 1.0mm pitch for their UDH hangers:

“Thru axles (D) must be compatible with UDH

and include a M12x1.0 thread pitch and thread

length measuring 12.7 mm.”

But does a UDH hanger (and the UDH spec dropouts) really necessitate a thru axle with a 1.0mm pitch?

As I just found this out the hard way (accidentally bought the wrong axle…): Yes

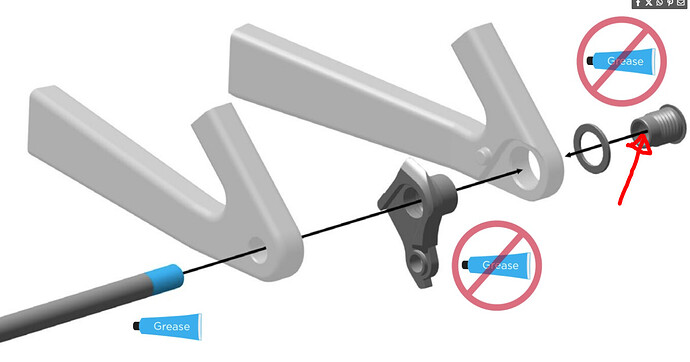

The part that engages with the thread on the axle is part of the UDH. This “Bolt” for lack of a better description has a pretty coarse LH thread on the outside that holds the actual hanger on the frame, and this 12x1.0mm thread on the inside where the axle threads into.

Of course, one could fabricate a different bushing with a different thread pitch, but if you buy an UDH it’s going to be 12x1.0

Yes, a 1.0mm TP. I have six feet of shelf space dedicated to the UDH-specific skewers we make.

Awesome guys! That answers it ![]()

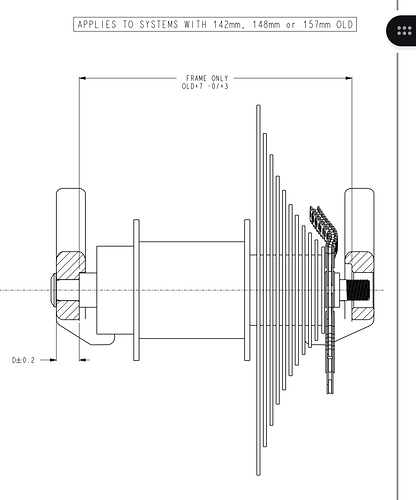

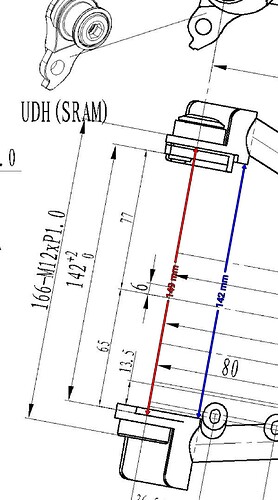

If I’m reading the UDH specs correctly, the dropouts of a frame designed for UDH are 7mm further apart than with a non-UDH frame and that extra 7mm is added only on the drive side, i.e. only the drive side dropout is moved further outwards (by 7mm):

This would produce the following drawing. The dimensions that are +7mm are red and blue:

With 142mm OLD and UDH, does the blue dimension necessarily have to be 142mn and the red one necessarily 149mm?

Note: the 65 and 77 come from the 6mm rear triangle offset.

That is correct. The UDH is 7mm from the axle seat to the outside shoulder. The 142 and ergo 148 O.L.D. still have to be centralised to the frame centre line ( or it coule be offset if you want to run an assymmetrical wheel). For some that means an assymmetrical rear end, where others have produced an NDS drop out that sits outboard by the same 7mm. I have done everything from 0mm to 7mm on the NDS but I’m not settled on what the best is. Brake mount and stay locations should be a driver in your design. If the touted UBH (Universal Brake Hanger/Mount) is brought in its a safe bet it has a 7mm working thickness as well.

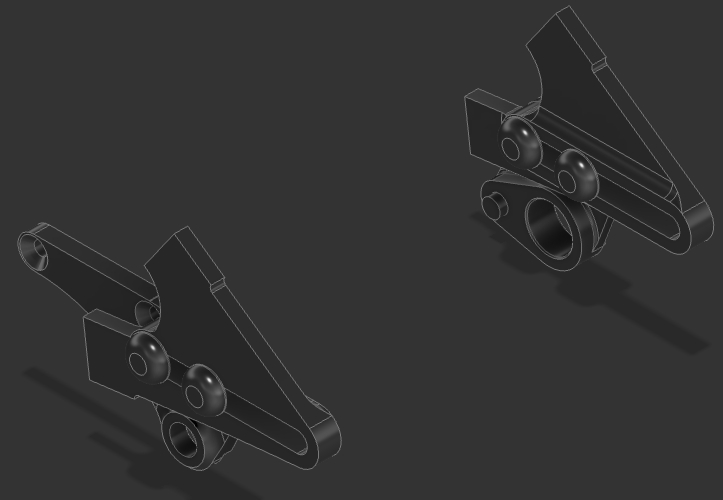

in a total about-face i’m drawing some dropouts which need to be UDH and T-type compatible, you’ve (,you know who you are,) shaken my MTB geometry tree, so I’m building a bit of a test rig.

i’d use the obvious solution from PMW but for a desire for 40mm of rear centre adjustment…

i’ve re-read the thread and had a look on the official site,

can someone point me in the direction of the clearance mask (s) or where they come from?

thanks.

(edit for a better screenshot (40mm adjust), for posterity)

I found the clearance masks in the UDH 3D file when I downloaded that from SRAM directly I think but I can’t find the page I downloaded it from anymore

Edit: found it!

https://www.universalderailleurhanger.com/

ah yes thanks,

not sure how I managed not to find that on the first pass…

it is in that zip folder alongside the PDFs

cheers again

Has anyone used the C82 allotec dropouts for a t type transmission? Just want to confirm they’re actually compatible with t type, I’ve only used them for normal UDH hangers and not been hands on with loads of t type mechs.

I have not used them, but if they work with UDH hangers, they will very likely work with T-type.

I have those dropouts on a bike and I can test it out on Monday at work if nobody else responds by then.

Yeah I’m being slightly paranoid I think but wanted to make sure. I’ve made enough frames slightly wrong because I wasnt as paying attention don’t need anymore hah

Ah man that’d be super handy if possible thanks!

Not personally but several customers are using this setup and I’ve had no reports of issues.

I have however read a review of another brands bike with the same dropouts stating “T Type derailleur can slip”. My assumption was that the knurled ring was only biting into powder coat rather than metal.

But that was just one reviewer on one bike and like I say, no negative reports otherwise.

I’ve had the same happen on bare titanium once or twice.

My theory is that the knurled ring struggles to bite into harder materials than carbon fibre and aluminium.