You’re right, I’m sure it was too cold. I was running 85 amps, 33% time on. 33% peak, 33 Hz. 0.065" wall thickness. I’ll crank it up a few notches and see how the next one goes, thanks for the tips!

What filler and size?

When I do a tube to a printed part I use 125a, 12% background, 15% time on. This is for .035” to printed part. I use .045 ER312 for filler.

Filler is .045 ER308

I prefer ER312 for its flow characteristics but 308 is very close.

@BS_Industries I just welded up a very similar joint on my frame and had the same trouble. It’s a tough joint to weld. Good luck! I hit the weld surfaces with a file to remove a skin that I’ve found on the surface of some printed parts.

Thanks for the tips @Neuhaus_Metalworks

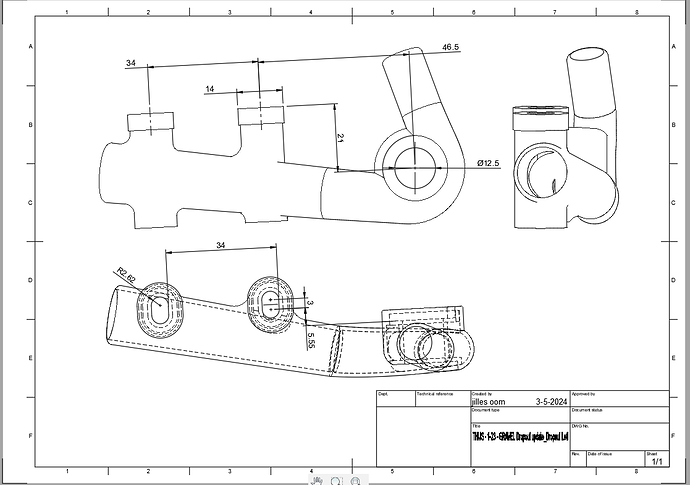

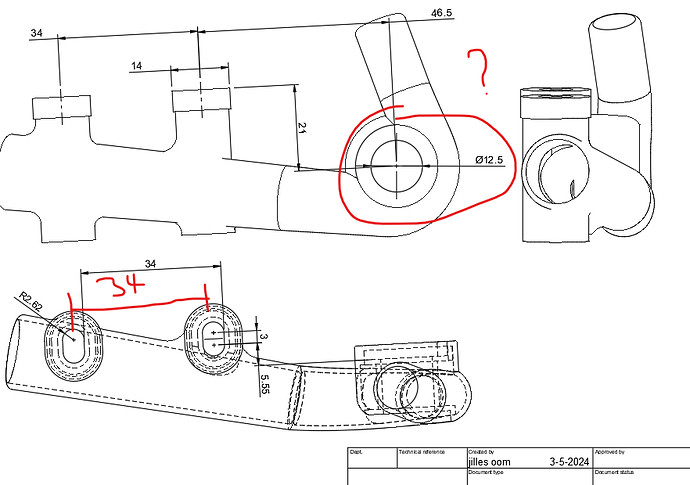

Hey guys, I have been designing these dropouts for thru axle, and 160mm flat mount disc brakes. my first attempt printed well and after a few tries i got it relatively well mounted to the chainstays. But as it turned out my dimensions for the disc brakes were way off. For my second attempt I wanted to Show it here so I don’t waste more time and money.

The thing im least certain about is the 46,5 from centre axle to first bolt hole.

3d printed dropout lefft.pdf (186.9 KB)

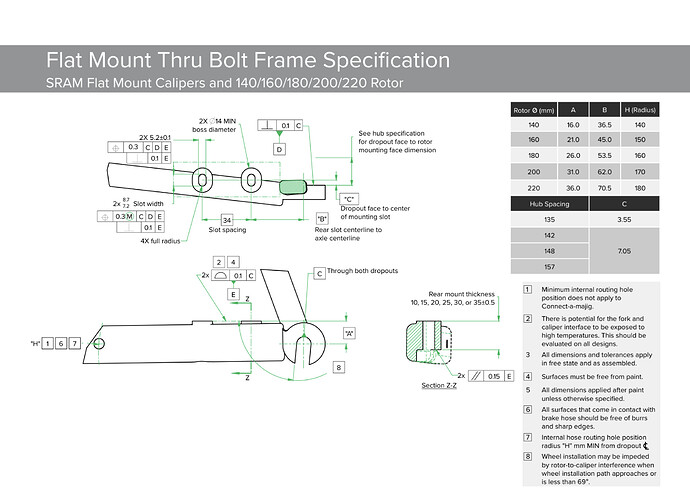

I’m not sure where you’re getting the 46.5mm number from. For 140/160mm rotors it would be 36.5mm or for 160/180mm rotors (which it looks like is what you’re doing) it would be 45mm.

Otherwise it looks great!

Hey thanks for the diagram, I based most my design on that and then couldn’t find it anymore. Ill change the 46,5 to 45 and I think it will work then.

@liberationfab is correct, the distance to the first boss should be 45mm

Just another quick check, are you sure the bore should be 12.5mm? Typically for a 12mm thru-axle, you need 12.1mm for clearance. For 3D printing, you almost want less so you can ream out the inevitable non-roundness.

As Daniel sad. 3D printing isn’t super accurate. It’s pretty good though but you need to design for any assembly surfaces to be post machined. I’ve found for example if the axle hole is modelled at 12.0mm it will also come in a fraction undersized which you either drill or ream out to size.

Just thought I’d share my 3D printing experience with the group – printed from Al10SiMg, with just a simple shell with variable wall thickness of 3mm at the stem clamp all the way down to 1.5mm at the bar ends. Printed in one piece with two exit holes for powder to escape, and I used 3DPBS to have them printed. So far it’s holding up nicely in the test rig and passed fatigue testing (1000N on each end, out of phase, 30,000 cycles), but I think it’s still overkill on the wall thickness. They’re designed for track sprint events and need to hold up to the massive forces coming out from the riders.

Can anyone commenting on printing with aluminum compared to titanium? I have more experience with aluminum in general so was leaning towards that, but looking here it seems titanium is more common. And brands like the Atherton bikes have 3d printed titanium lugs on the expensive bikes and CNCd aluminum lugs on the “cheaper” bikes.

I was looking to use aluminum pipes and aluminum lugs for a front triangle (see my topic here: Is it feasible to build a bonded aluminum frame?), my first thought was to order them CNCd but printing seems to be cheaper and easier to prototype with plastic so trying to learn about that now

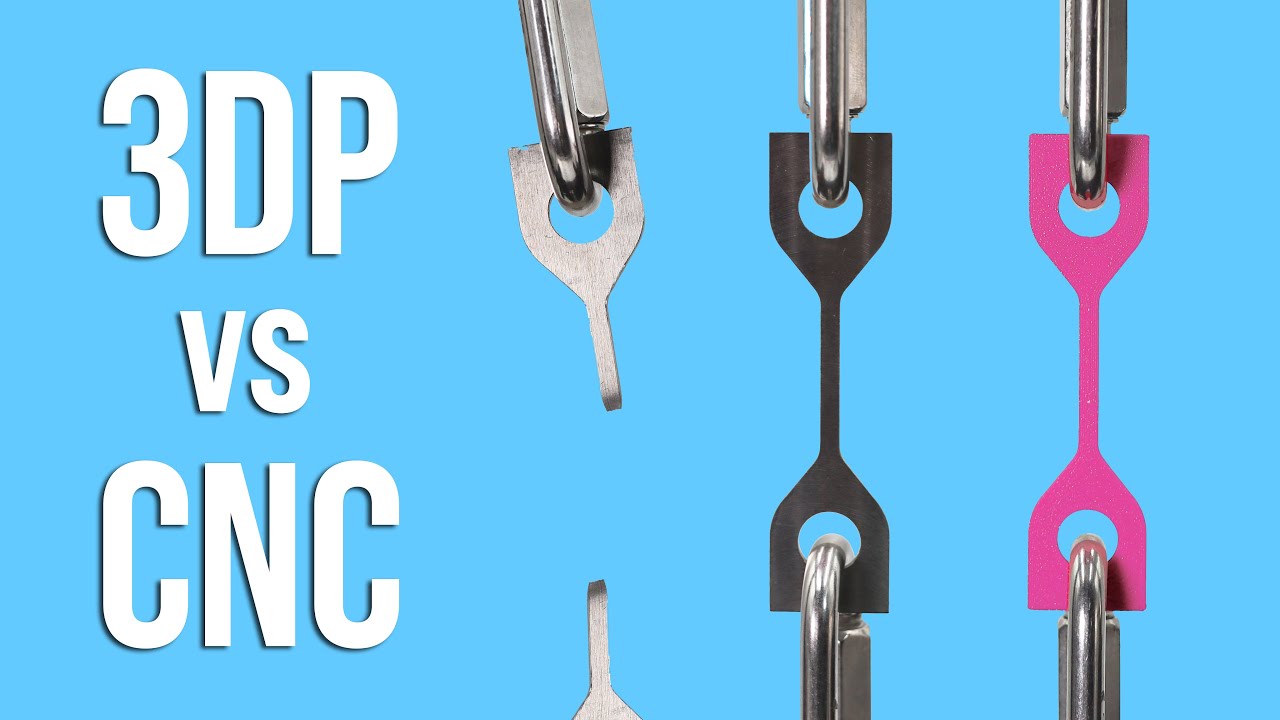

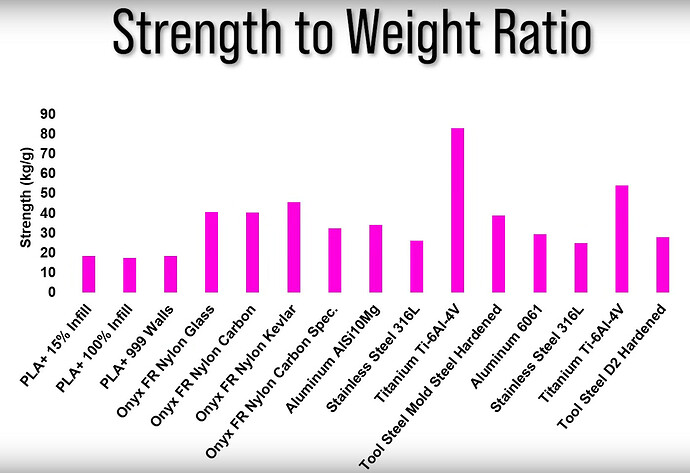

Found this video comparing different 3d printed and cnc:d metals. Surprisingly 3d printed was stronger for all metals then cnc:d?

The clear winner in this chart is the 3d printed titanium, so maybe thats why its used ![]() Aluminum seems to do OK though, but will be heavier

Aluminum seems to do OK though, but will be heavier

Wow, that 3D-printed titanium result is surprising—opposite of what I would think. Maybe the 3D-printed Ti ended up being heat-treated by the printing and baking process.

In general, there are no bad materials, just how they are designed. I think titanium lugs are used simply because those types of bikes are sold as premium, luxury objects.

This is an example of Pinarello’s aluminum 3D printed frame:

Ganna’s frame was printed by Mythos. I spoke to them once and they said their Scandium alloy is some proprietary aluminium they have created just for printing. It may sit somewhere else on that graph because of that.

One big thing that swayed me to Ti for my printing endeavors is the reduced possibility for galvanic corrosion. You have to be way more careful about that with aluminum. I’m not terribly worried about any small fitup issues where CF touches Ti, but I would not want that if I was building with aluminum. One of my big takeaways from the SU&BB interview with Frameworks was the degree to which they ensure a corrosion-free bond with surface treatment, bond gap enforcement, and precise fitup.

The classic aluminum alloys, like 6061, are not readily printable due to hot cracking so you will tend to see the casting grade alloys like AlSi10Mg and AlF357 (which are much weaker). There are some tweaks done to aluminum alloys to make them printable but you will have a hard time finding a contract manufacturer with capacity to print 6061 RAM or Scalmalloy for you. My guess on why you see more Ti64 printing than aluminum is because of this alloy availability issue and the fact that Ti64 is difficult to machine and aluminum is relatively easy, making CNC a cheaper route. I’m also surprised at those strength comparison results… be sure to look at material data sheets and compare for yourself before making any design decisions off that!

The other option of course is to use 316SS. It has great strength characteristics and elongation and like Ti won’t react with the carbon or corrode from moisture.

Am I right, there are two very different values for the same Titanium?

Yes and no… Watch the video!